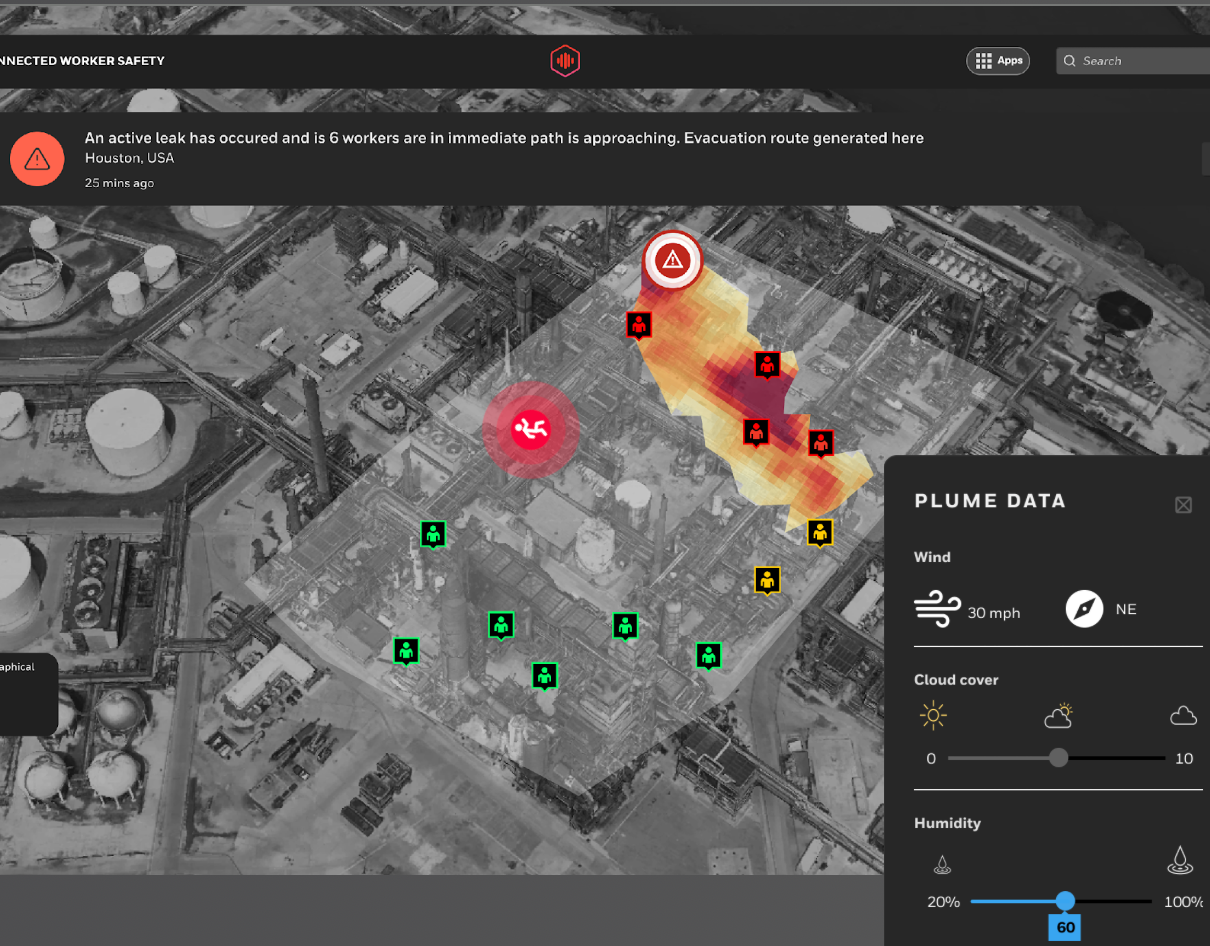

SAFETY SUITE PROJECT

Aggregating Alarms to Prevent Fatigue

Reduces cognitive load by replacing 25 alarm notifications with a single spatial 'Hazard Zone' visualization. Operators get instant context and worker indicators are clustered together when zooming out to assess the situation.

Scenario:

An operator monitors a nearby gas leak that triggered an automated evacuation response and visualization of the gas plume's predicted path with affected workers in harm's way.

An operator monitors a nearby gas leak that triggered an automated evacuation response and visualization of the gas plume's predicted path with affected workers in harm's way.

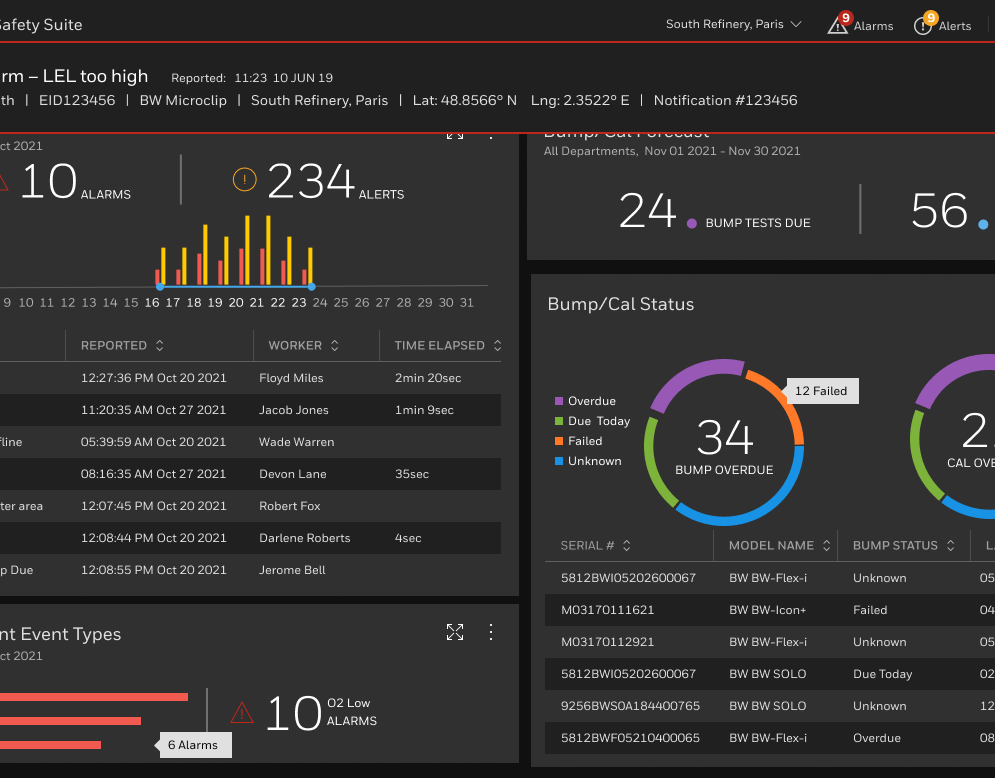

SAFETY SUITE PROJECT

Instant Context for Rapid Intervention

Instead of cross-referencing a device ID with a shift log discover which worker is in trouble, data in the alarm card displays relevant information allowing the operator to continue to monitor other devices in the area.

Scenario:

When a worker's device triggers a 'High CO' alarm, the operator's system isolates the signal immediately and displays the real-time gas reading (21 ppm) alongside the worker's identity, coordinates and device readings.

SAFETY SUITE PROJECT

Predictive 3D Hazard Modeling

A unique visualization that offers first responders a different perspective from the traditional 2D alarm indicators. The plume's saturation signifies where density is greatest and which buildings, floors and city blocks are in clear and present danger.

Scenario:

A large-scale toxic gas event has released a dangerous plume into a heavily populated area. By combining terrain data with live sensor inputs, the operator can pinpoint the 'Leakage Point' and visualize the impact zone.

A large-scale toxic gas event has released a dangerous plume into a heavily populated area. By combining terrain data with live sensor inputs, the operator can pinpoint the 'Leakage Point' and visualize the impact zone.

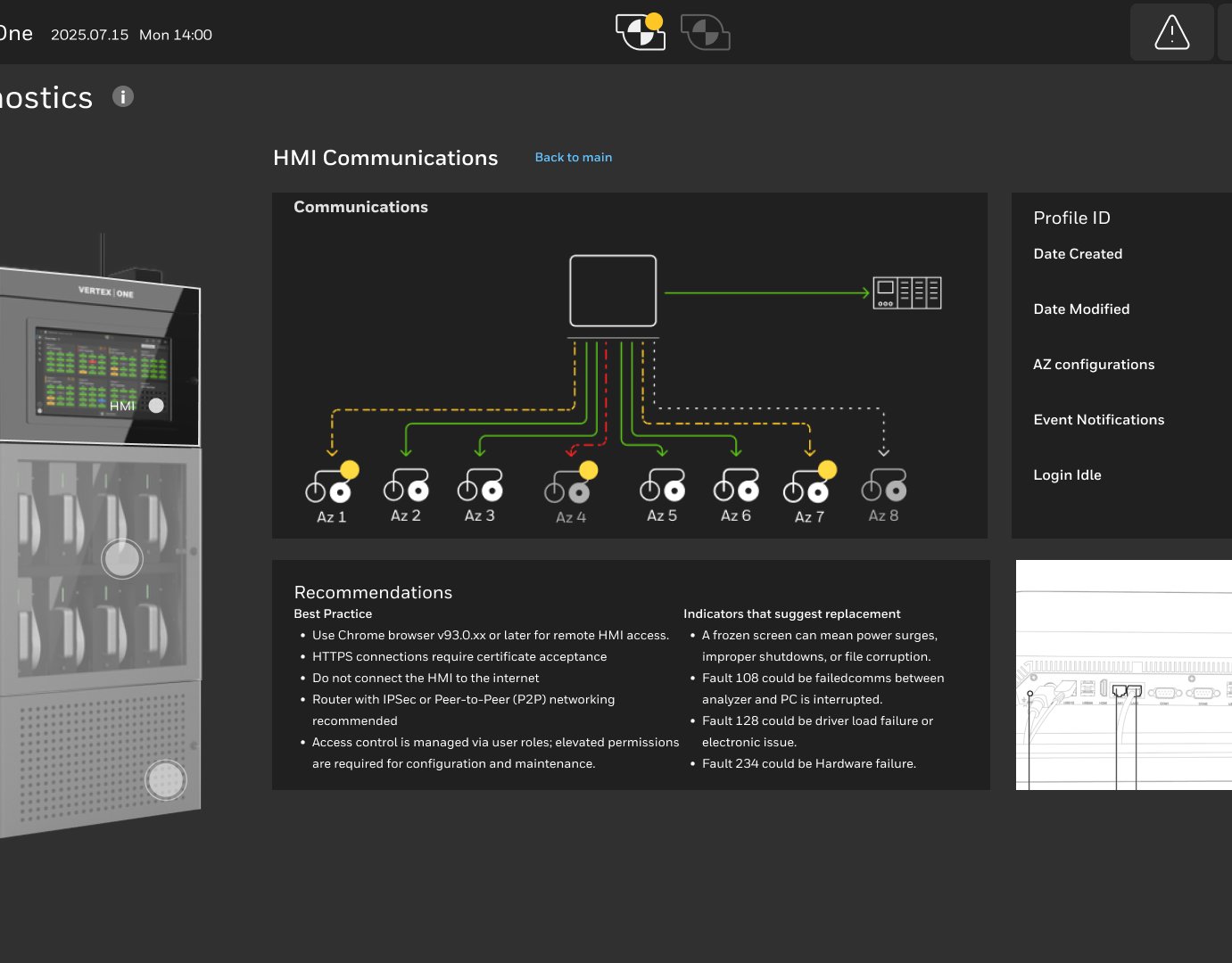

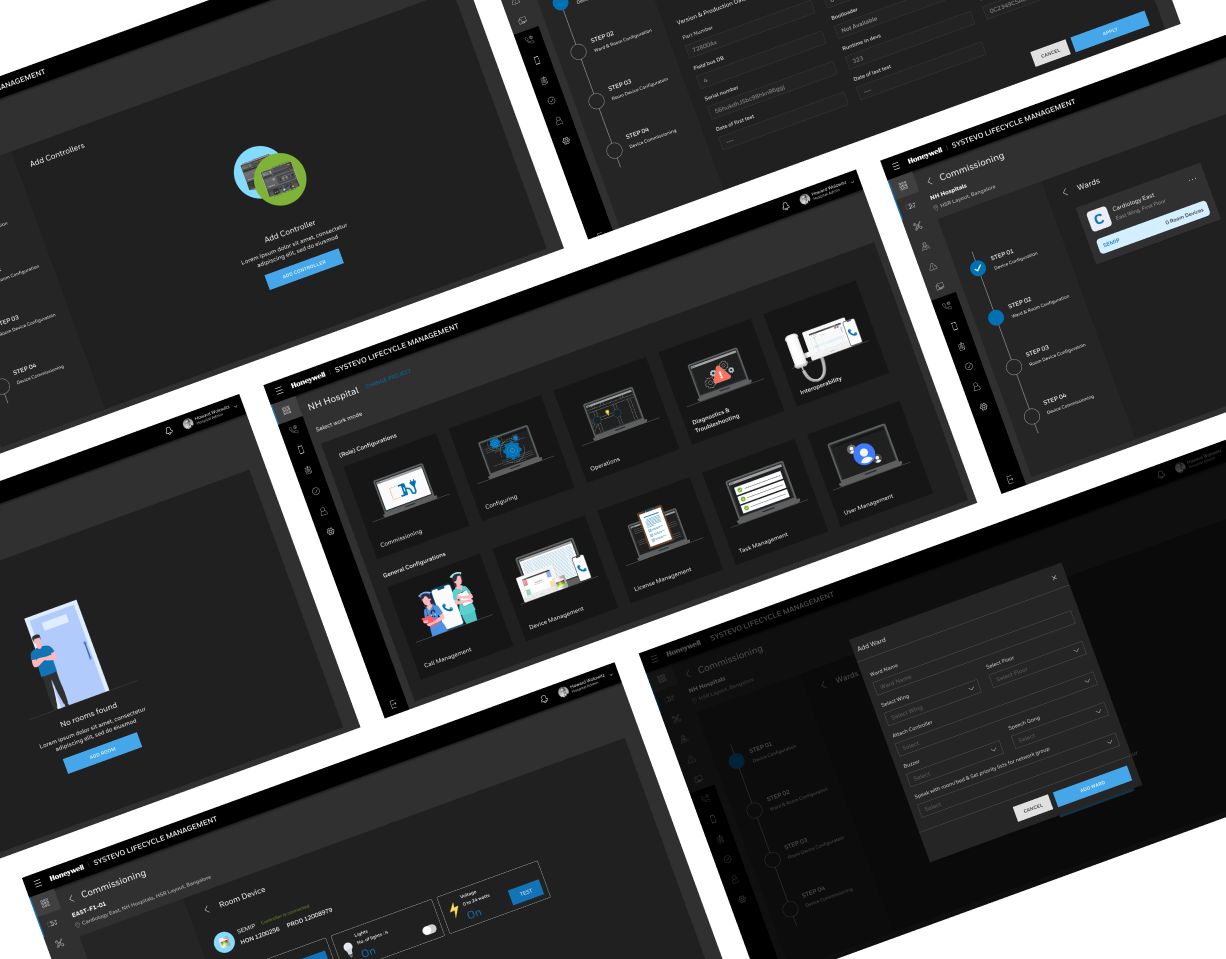

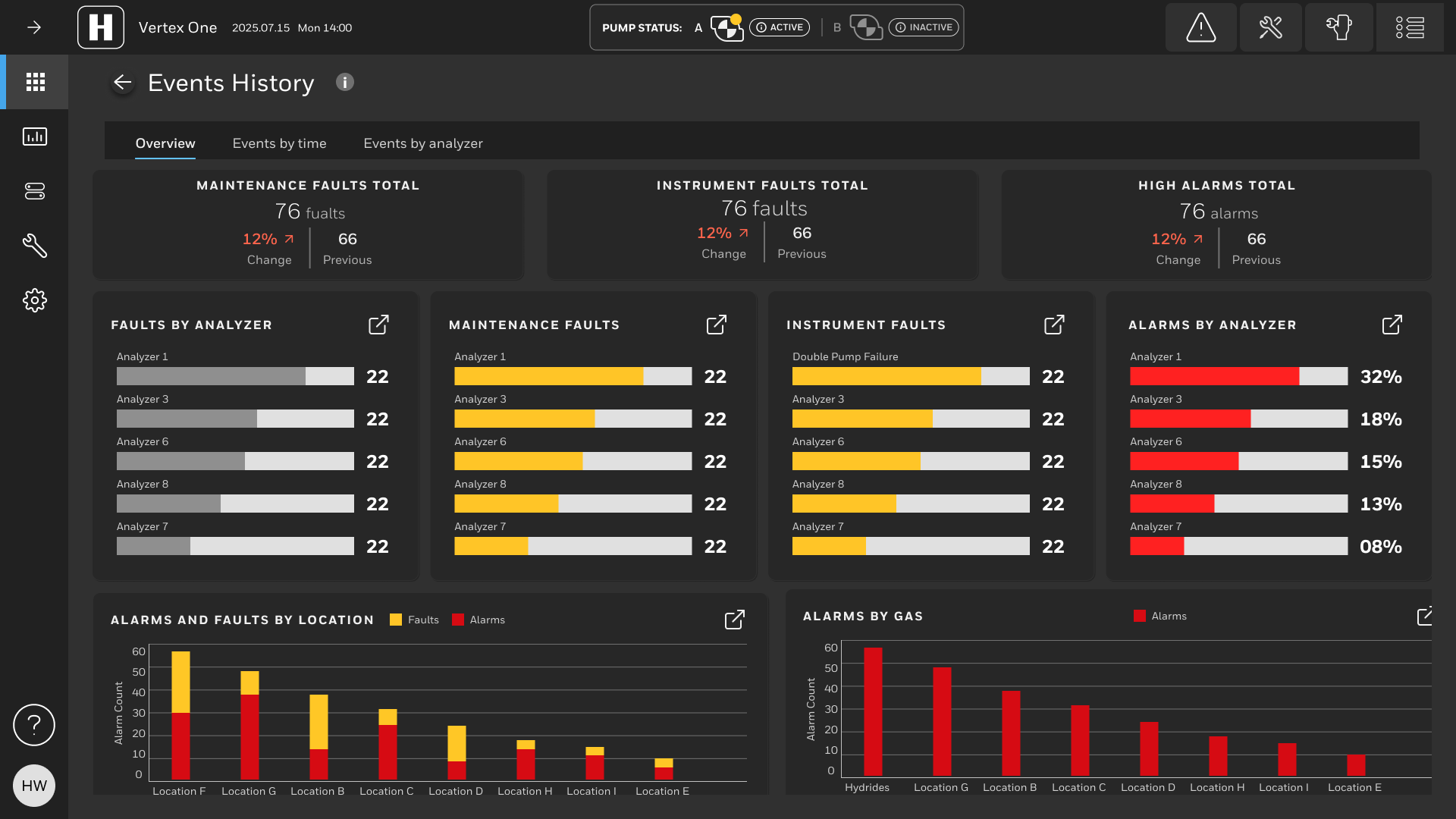

VERTEX ONE PROJECT

Event History and Analytics

Provides a comprehensive overview and visualization of system health trends while specifically tracking faults and alarms for the toxic gas monitoring system in semiconductor fabs, VertexOne. The design uses the accessible "Honeywell Forge 2.0 Design System" with modular cards, keeping distinct data sets organized and scannable.

VERTEX ONE PROJECT

Focus Mode

By following ASM standards this design features a desaturated view of gas detection points. When an alarm or fault occurs it is extremely obvious where it happens, which sensor and which analyzer.

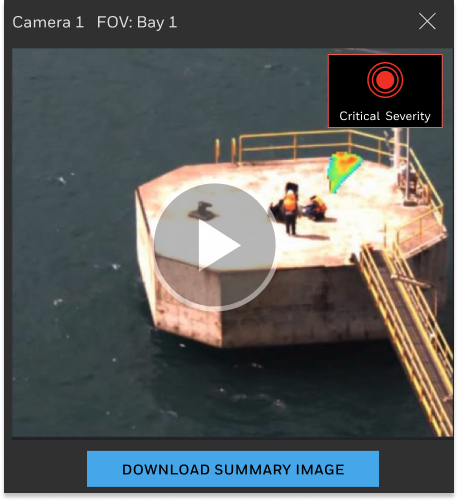

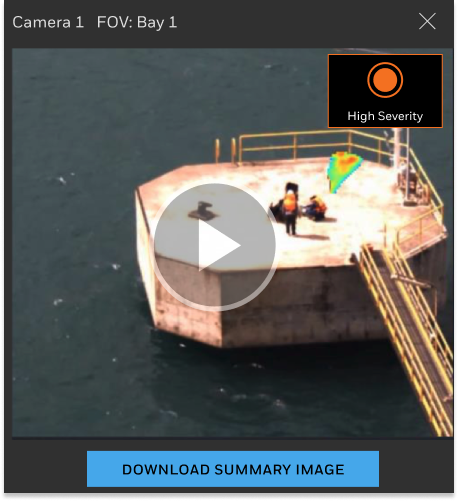

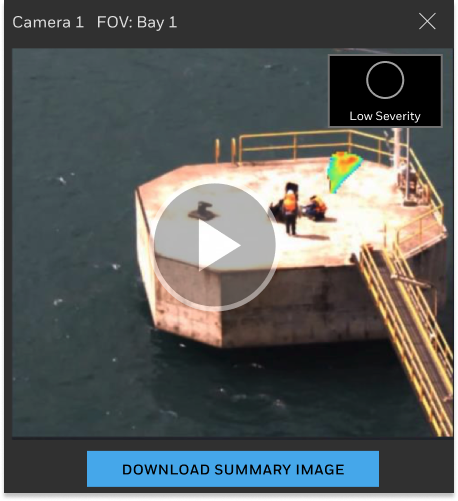

MASS METHANE PROJECT

Alarm grouping and viewed state

In this methane leak detection application designed for Honeywell, alarms and alerts are grouped by incidents to keep nuisance or redundant noise to a minimum. Only new alarms have the red border and the latest incident is automatically displayed at the top of the list. Operators can view, resolve or favorite the alarm for sharing with technicians on site.

Scenario:

A methane leak has triggered the alarm panel as operators are able to diagnose the incident quickly since related alarms are grouped together. Operators also can view a video snapshot of the event.

A methane leak has triggered the alarm panel as operators are able to diagnose the incident quickly since related alarms are grouped together. Operators also can view a video snapshot of the event.

MASS METHANE PROJECT

Timeline view of alarms

A "unique timeline Gantt chart" to display the historical data of methane leaks. Instead of filtering and sorting through data, the operator is able to quickly visualize multiple leaks spanning across days, make approved edits and create a report.

Scenario

Operators digest temporal data quickly and organize historical links by editing the notes and timelines of previous leak events.

Scenario

Operators digest temporal data quickly and organize historical links by editing the notes and timelines of previous leak events.

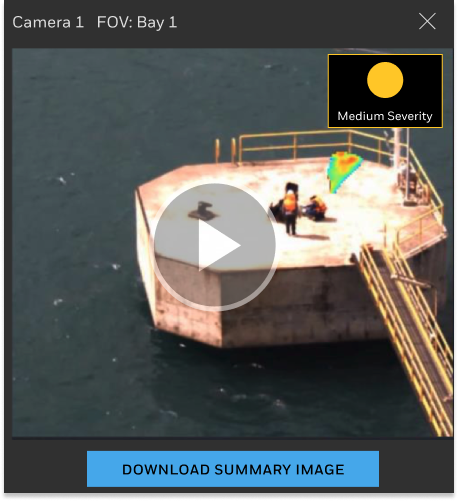

MASS METHANE PROJECT

Severity levelsA four-tier alarm classification system categorized methane leaks based on severity, concentration and danger. The top row of images represents modal windows that leak events at various levels of severity.

Scenario:

An operator is able to confidently assess the alarm before diving into the details to diagnose the problem. Should the alarm be shared or should it be acknowledged or dismissed?

An operator is able to confidently assess the alarm before diving into the details to diagnose the problem. Should the alarm be shared or should it be acknowledged or dismissed?

MASS METHANE

Training the data

A detailed view of a methane leak displays the status as unconfirmed or confirmed as well as other metrics like total mass, duration and flow rate. Then enables the operator to intelligently train the alarm management model on confirmed leak events.

Scenario:

An operator is determining the validity of leak event by considering multiple data sources and then training the model by verifying the event as accurate.

An operator is determining the validity of leak event by considering multiple data sources and then training the model by verifying the event as accurate.