EWS Project Overview

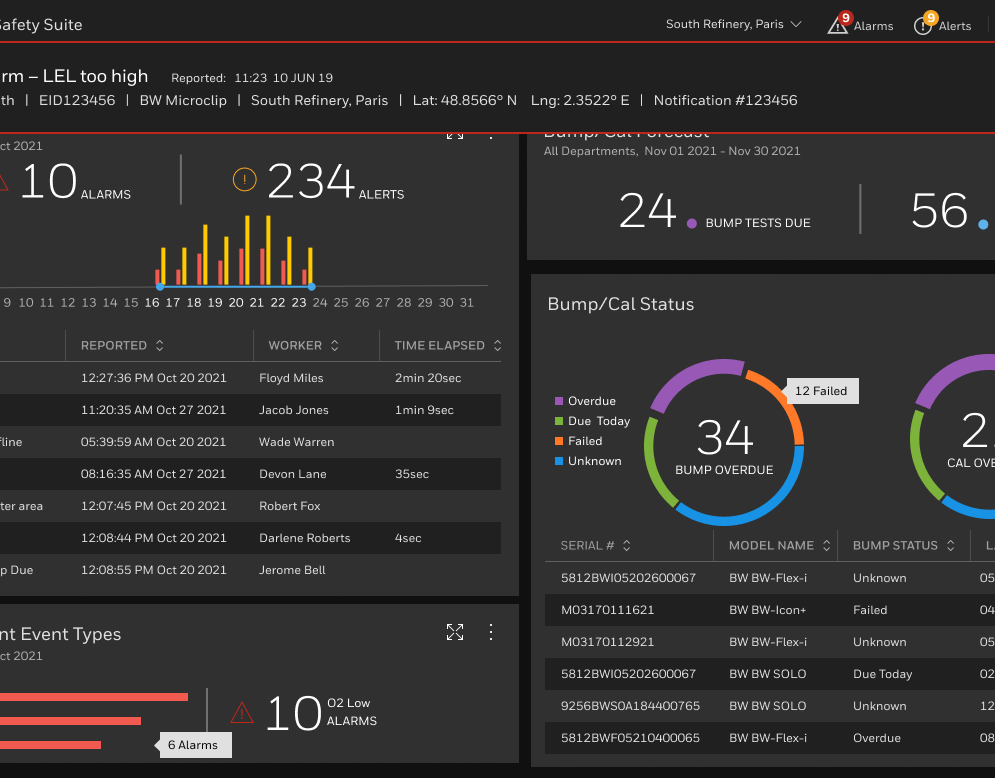

Enterprise Worker Safety (EWS) is Honeywell’s next-generation implementation of Safety Suite. The design goal is to transition a fragmented legacy gas-detection ecosystem into an intelligent, connected platform for industrial workers, safety managers, and technicians. It focuses on seamless device setup, device/fleet management (including check-in/check-out), and compliance assurance that is powered by trusted UX patterns, connectivity and AI that assists every aspect of a complex workflow.

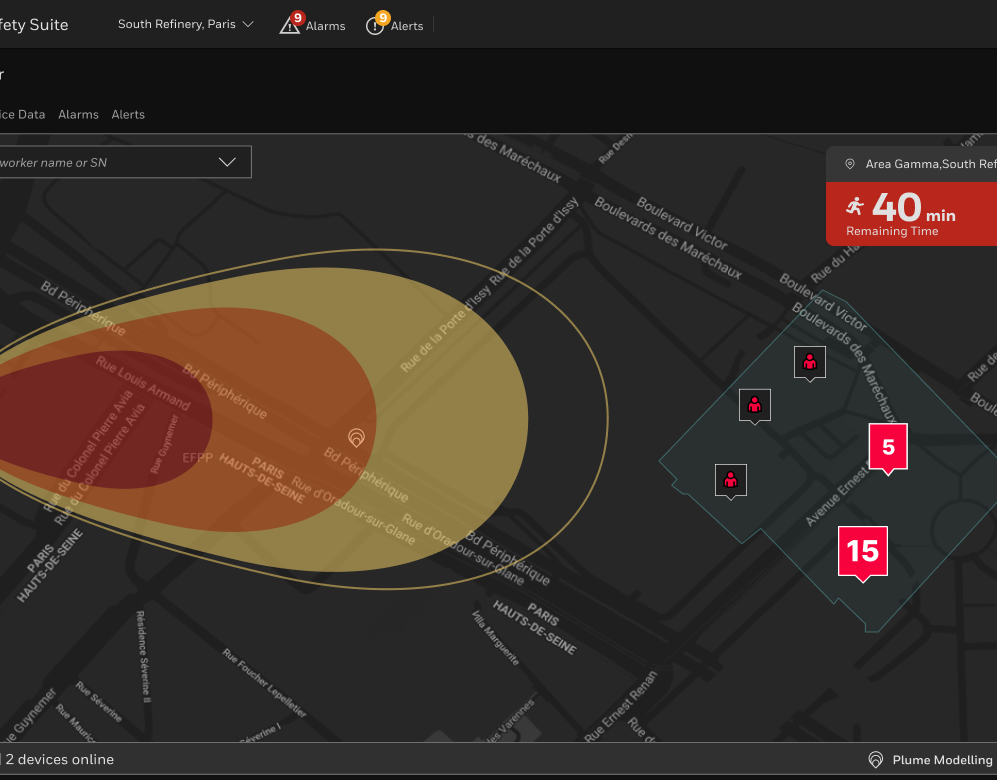

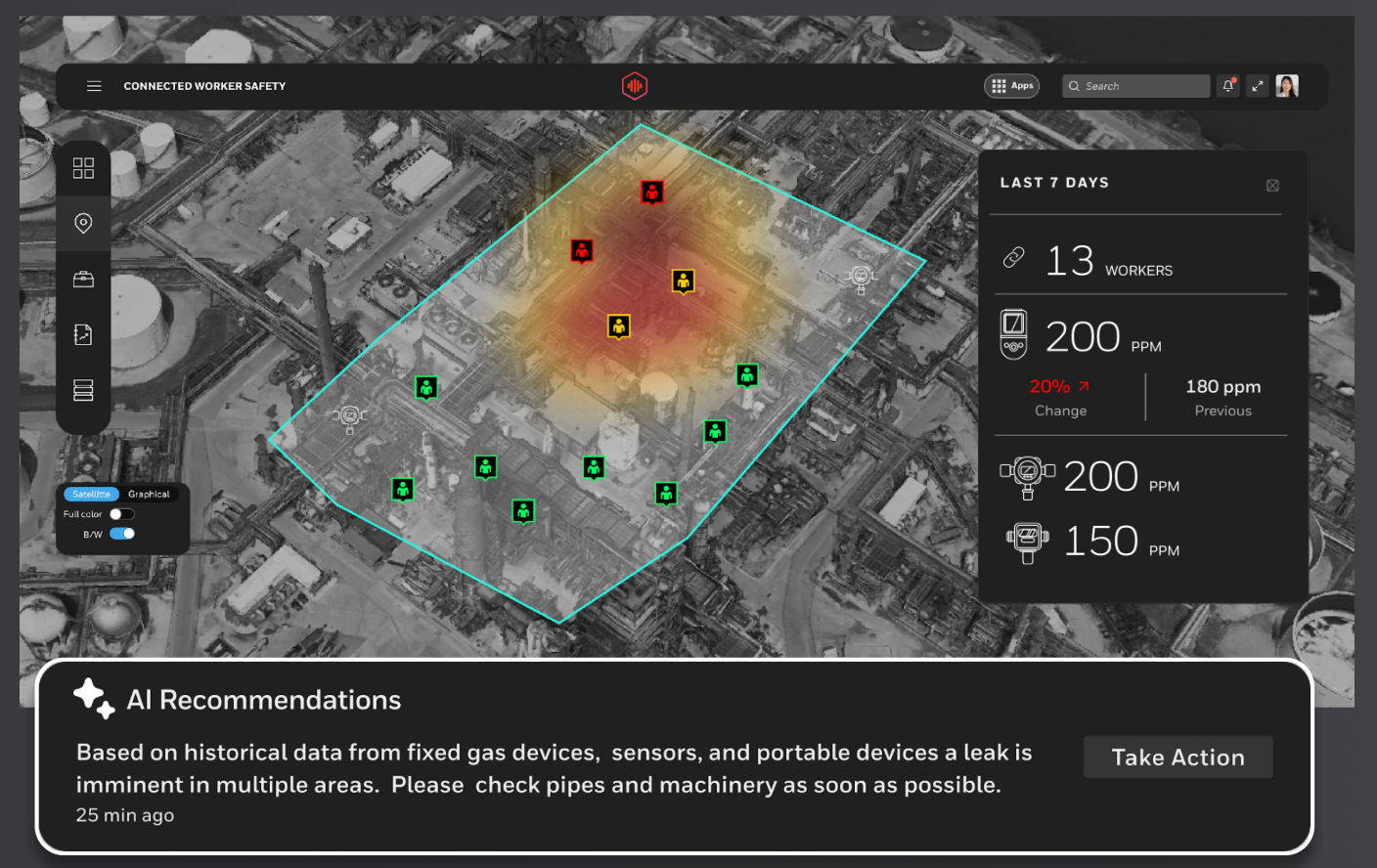

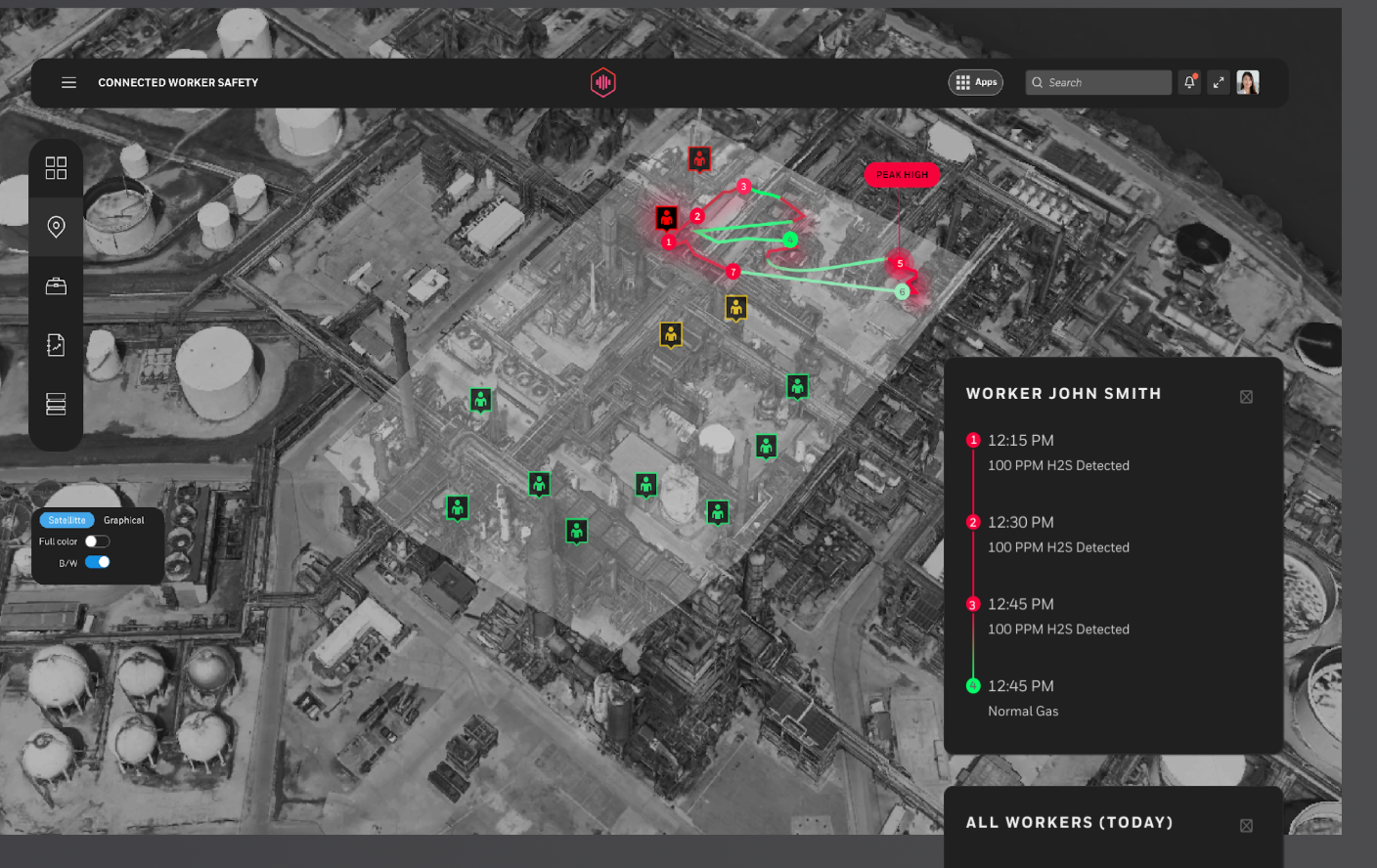

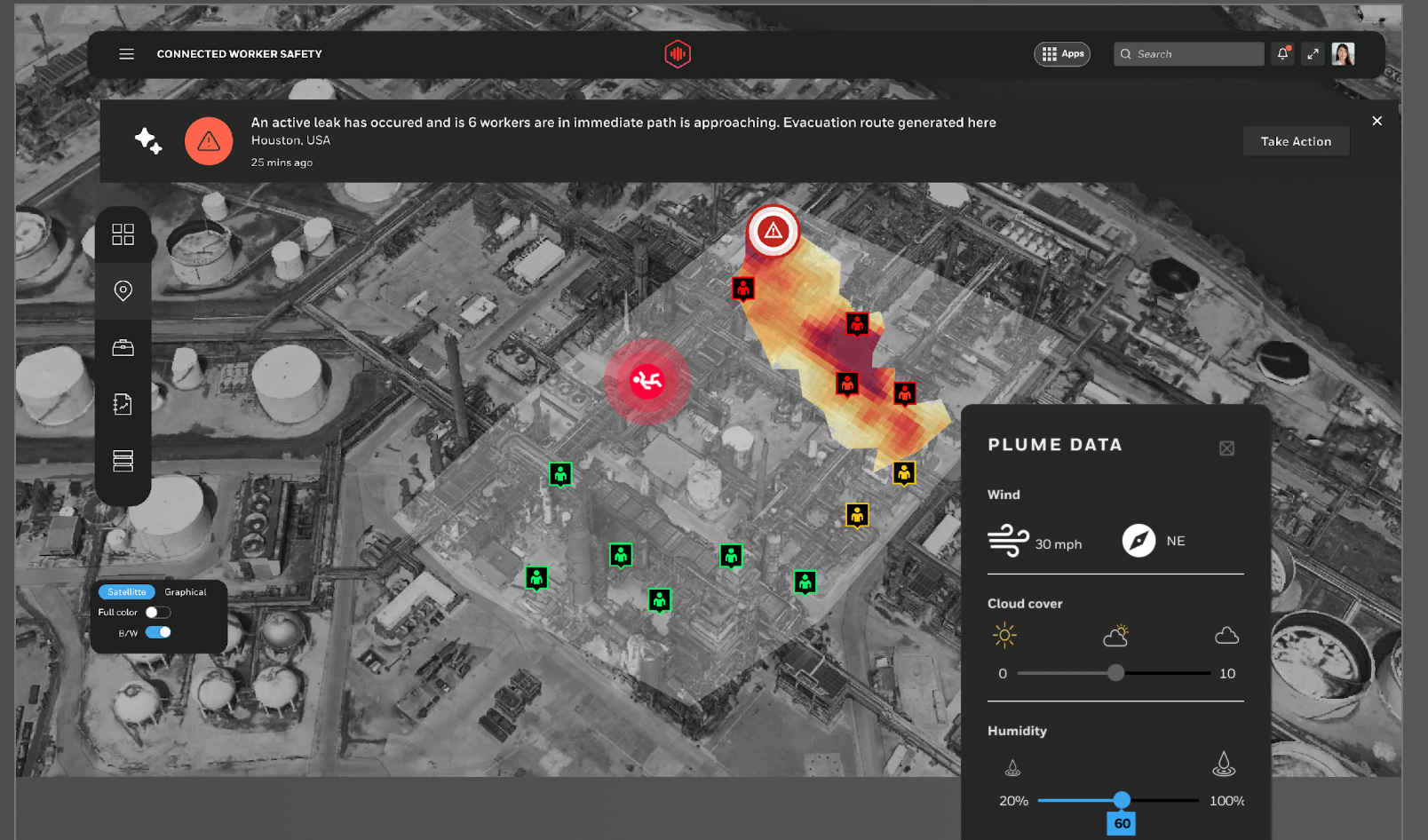

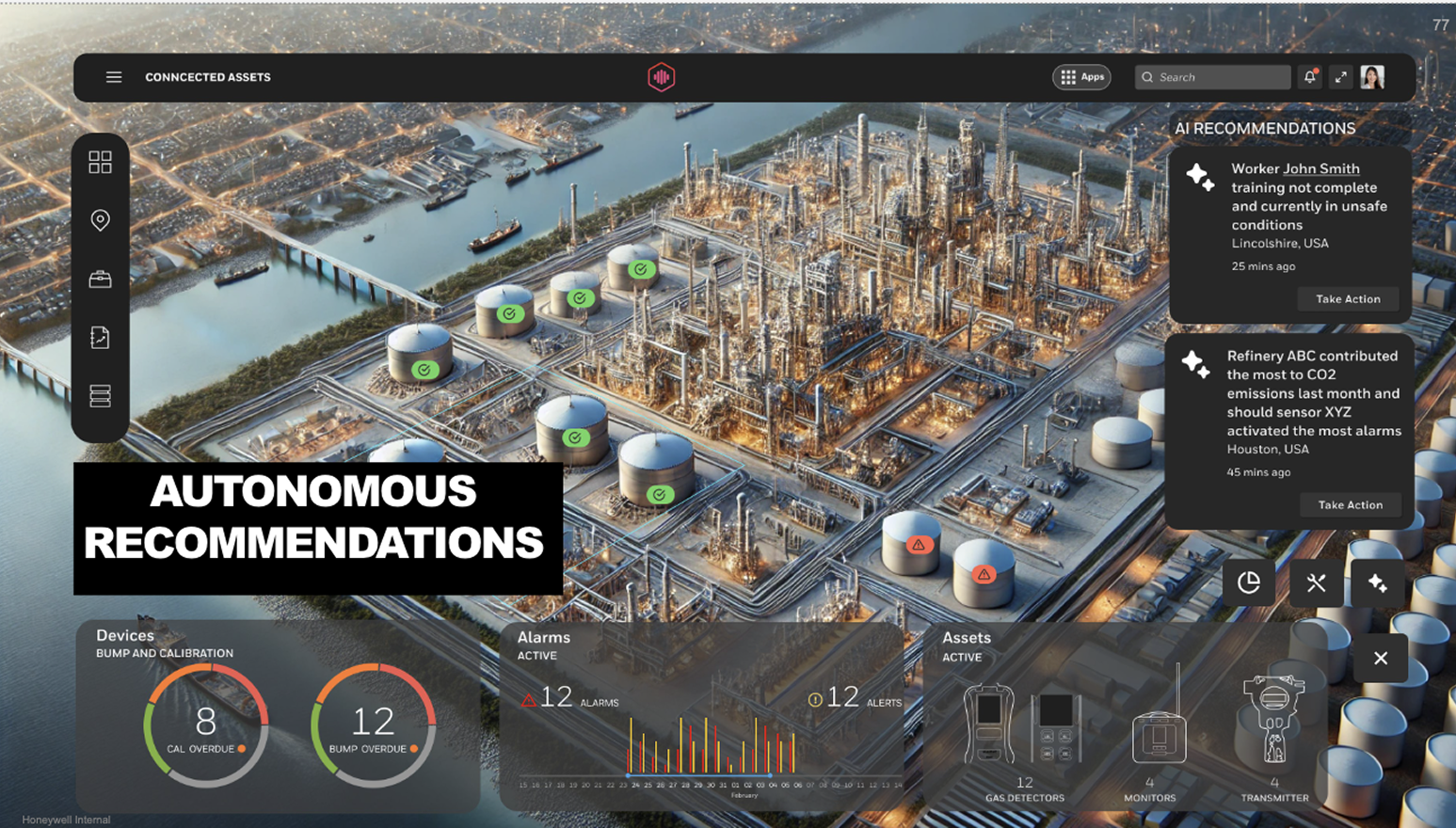

AI Recommendations, Satellite Imagery and Data Snapshot

Instead of simple data points, this concept employs a color-coded "plume" or heatmap (red, yellow gradients) onto a satellite map. The AI model's prediction of hazardous situations are established by calculating gas dispersion based on data logs and external environmental factors (like wind direction). Our philosophy is that AI should be about "augmentation," not just automation. Human operators have a transparent view of complex data, empowering smarter safety decisions. A snapshot of instrumentation metrics from the last 7 days and a recommendation gives operators actionable data and steps to take to save lives in high stress environments.

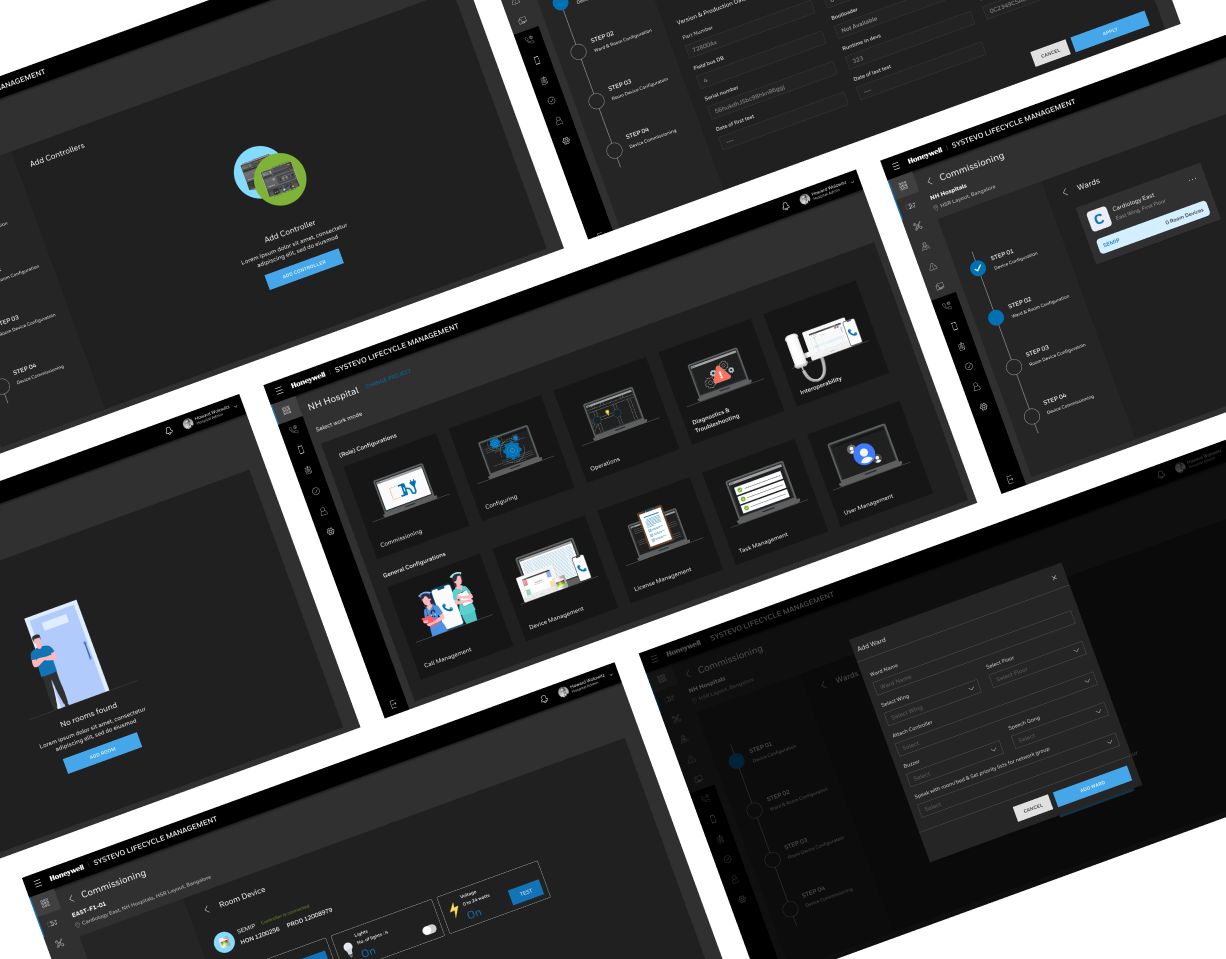

Action-based Design

By organizing actions into clear columns and categories: "Manage Assets," "Analyze Data," and "Manage Fleet" this home screen helps users mentally map asset management tools, data-rich compliance dashboards, and fleet management applications while reducing the cognitive effort required to use the software. Instead of dashboard overload, users see custom visualizations and progress bars immediately relevant to their role.

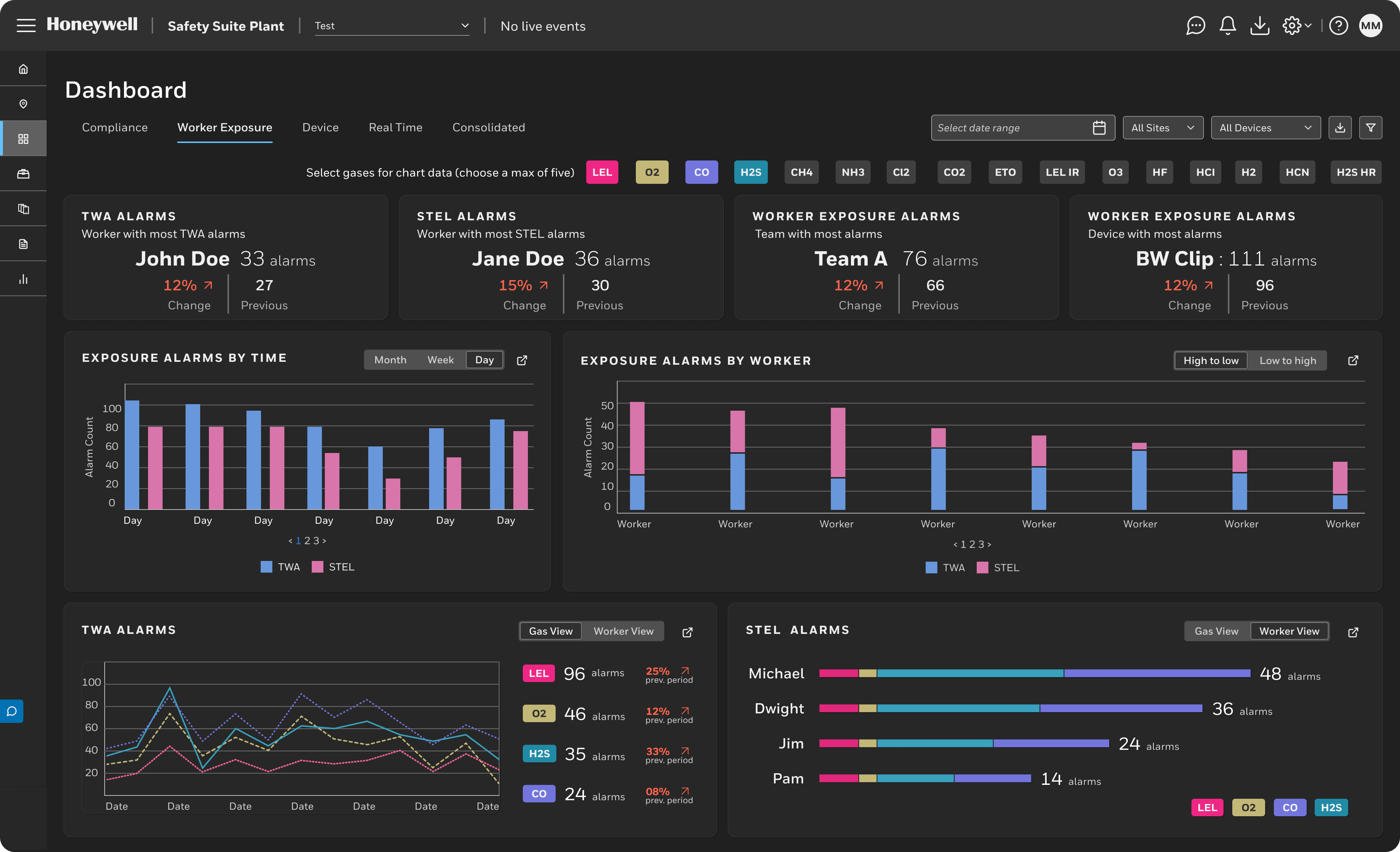

Accessible Design

Line chart visualizations are distinguished by dashes, dots instead of relying solely on color. The high contrast color strategy ensures that users with color blindness that can't distinguish red or green still interpret critical safety data accurately. Almost all users will be able to distinguish between blue vs. pink to understand the charts. Gas types are clearly designated with color combinations that meet WCAG guidelines and stay consistent throughout the experience

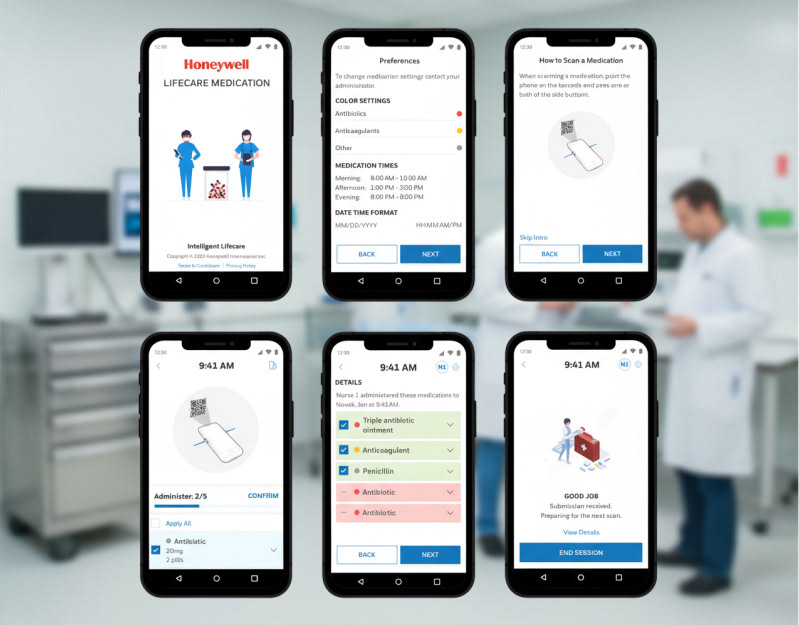

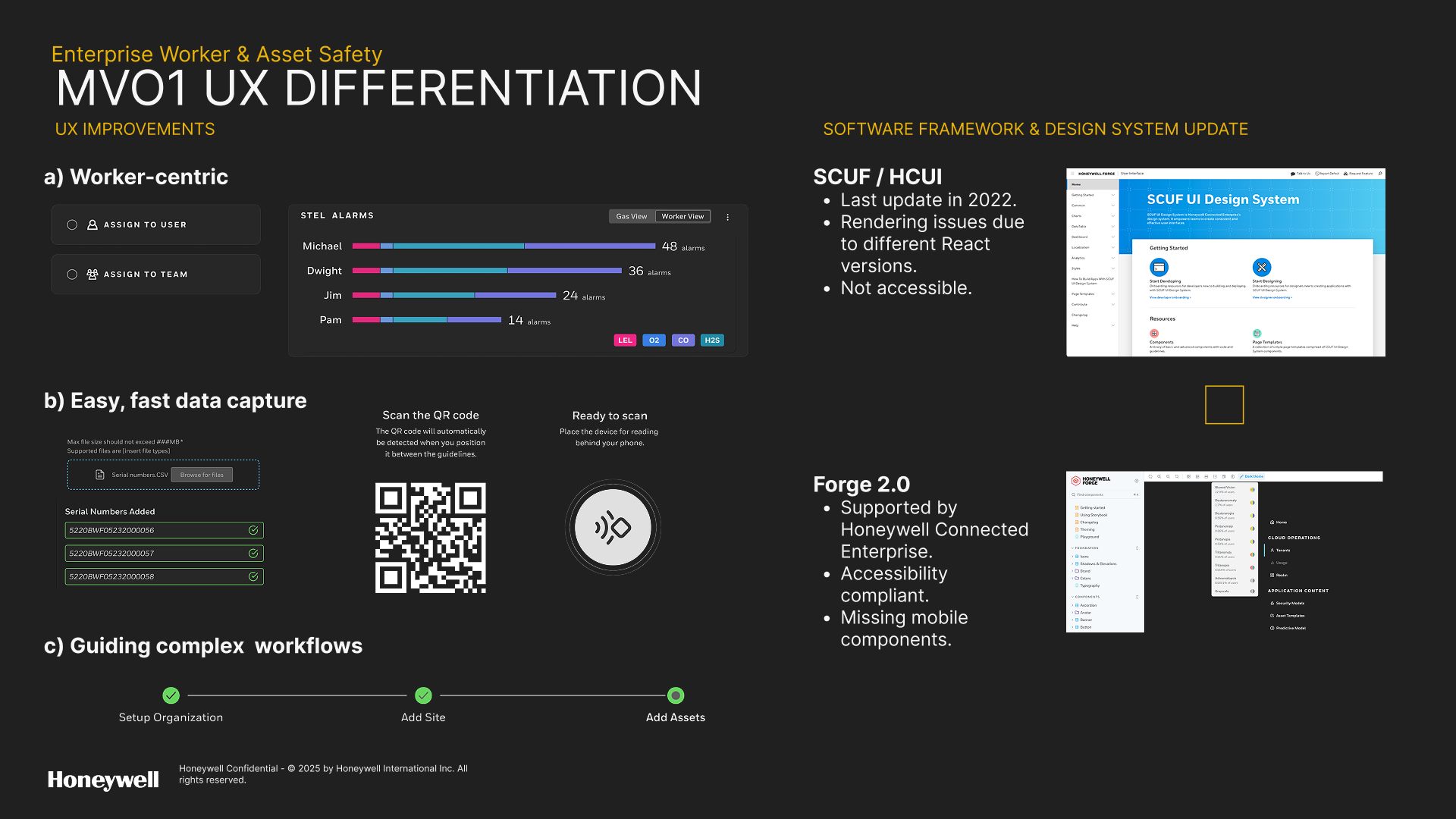

Strategy that differentiates

The Safety Suite redesign shifts to design principles surrounding a worker-centric model as the system makes safety more human and personal. Operators can instantly see who is at risk which allows for faster, more targeted interventions. By focusing fast setup and data capture the new strategy directly addresses the project's goal of decreasing customer reliance on tech support. By using QR and NFC technologies we were able to reduce time and errors associated with manually entering serial numbers for hundreds of devices. By guiding workflows with step-by-step visual trackers the barrier to start using the software is lowered which reduces the need for extensive training. Leveraging the latest design system, Honeywell's Forge Design System, the EWS software is more accessible to all users as the result of high color contrast and screenreader-friendly design.

Workflow simplified with guided onboarding and NFC/QR/BLE

Workflows simplified with guided device onboarding address the complex process of connecting devices to the application to trigger data streams. The cross-platform desktop/tablet/mobile experience presents multiple optimized pathways to connecting devices. including three distinct methods: "IR Cable," "Docking Station," and "Mobile App" (via NFC or Bluetooth). Illustrations and consistent feedback give the user more confidence and reduce friction when connecting devices.

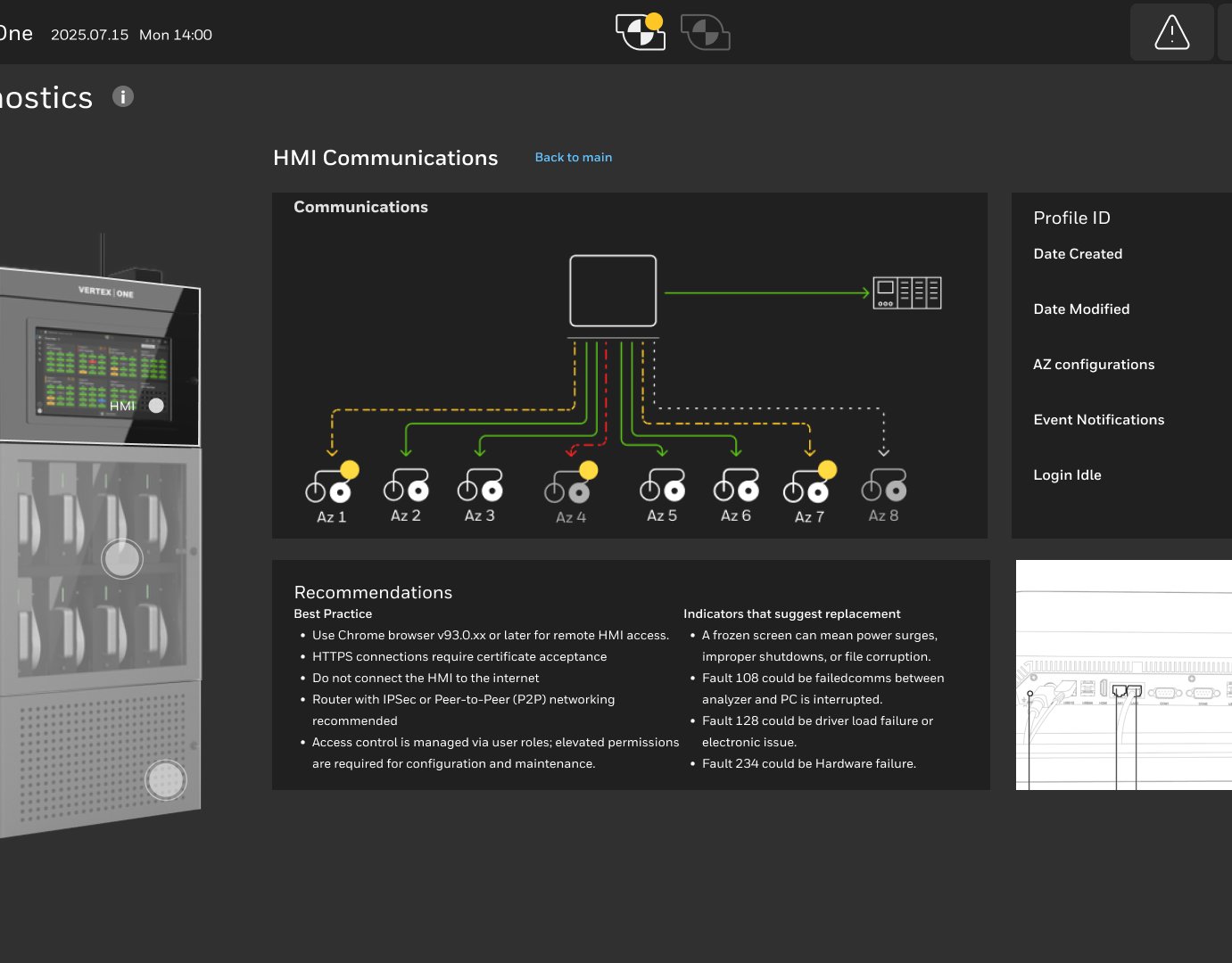

Design System 2.0

Migrating to "Forge 2.0" solves critical "technical debt" issues. By moving to a supported, accessibility-compliant framework, the platform becomes more stable, inclusive, and easier to maintain long-term. The non-destructive components reduced the likelihood of detachment, thus keeping the overall experience more consistent. A sister project, VertexOne is depicted below to demonstrate how component layers and placeholders are used to modify and customize.

Dev Hand off

Branching and merging of design files helped to keep the design team and developer on the same wavelength. More senior designers can approve or reject changes, formalizing the design process and reducing overwrite need. Design iterations are meticulously tracked preventing version control issues with developers following the wrong design iteration which is common in large projects.

Pages are designated with indicators of production readiness and design screens map 1-1 with development Jira stories and issues (e.g., "Sign up - EWAS-198 / 213"). This ensures developers know exactly which design belongs to which ticket.

Pages are designated with indicators of production readiness and design screens map 1-1 with development Jira stories and issues (e.g., "Sign up - EWAS-198 / 213"). This ensures developers know exactly which design belongs to which ticket.