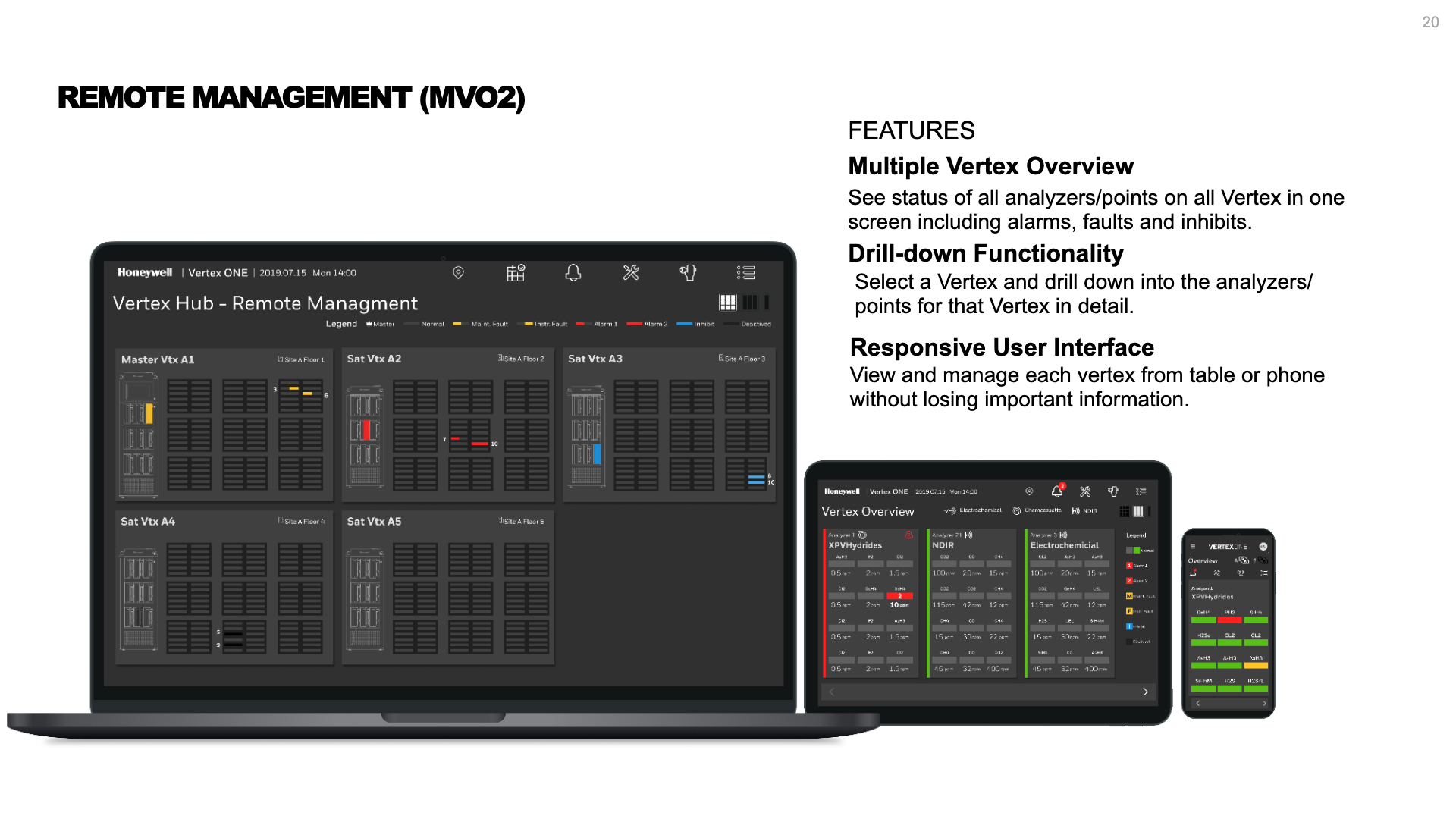

Designing with AI and Digital Twins for Actionable Insights and Larger system Integration

• Vertex Insights: Predictive maintenance and insights based on machine learning from historical fault and alarm data, with the goal of preventing costly downtime.

• Prediction Score: Recommended actions with the likelihood of costly events alongside clear indicators that these are AI-generated and should be supplemented with addition data sources.

• Vertex Assist: A conversational AI assistant embedded within the device enabling technicians to quickly ask natural language questions for troubleshooting help and maintenance schedules.

Focus mode included here so actionable alarms show up more prominently

Icon Assist can be turned on or off in preferences

Concepts, High Fidelity Prototypes and Dev Hand-off

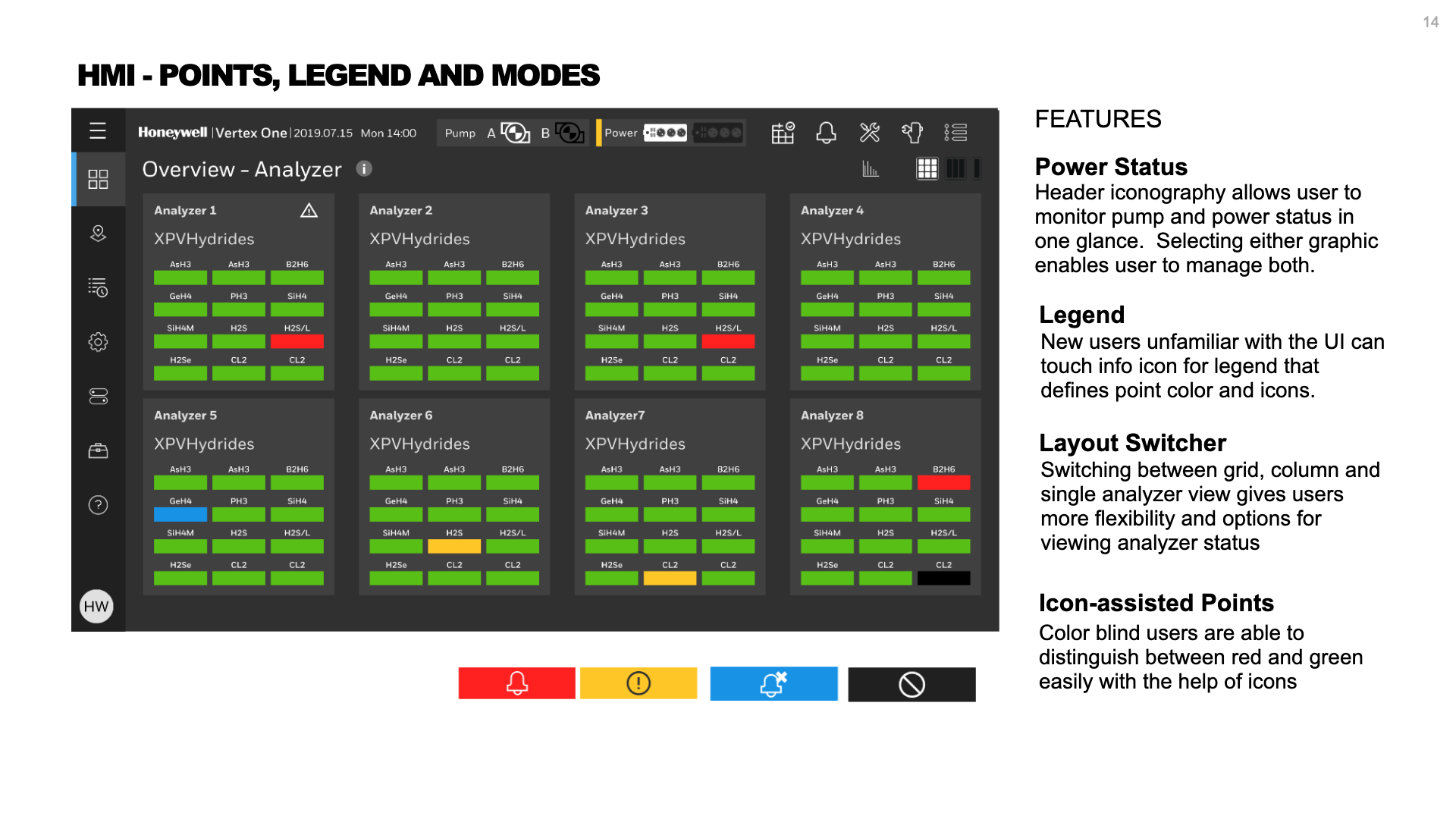

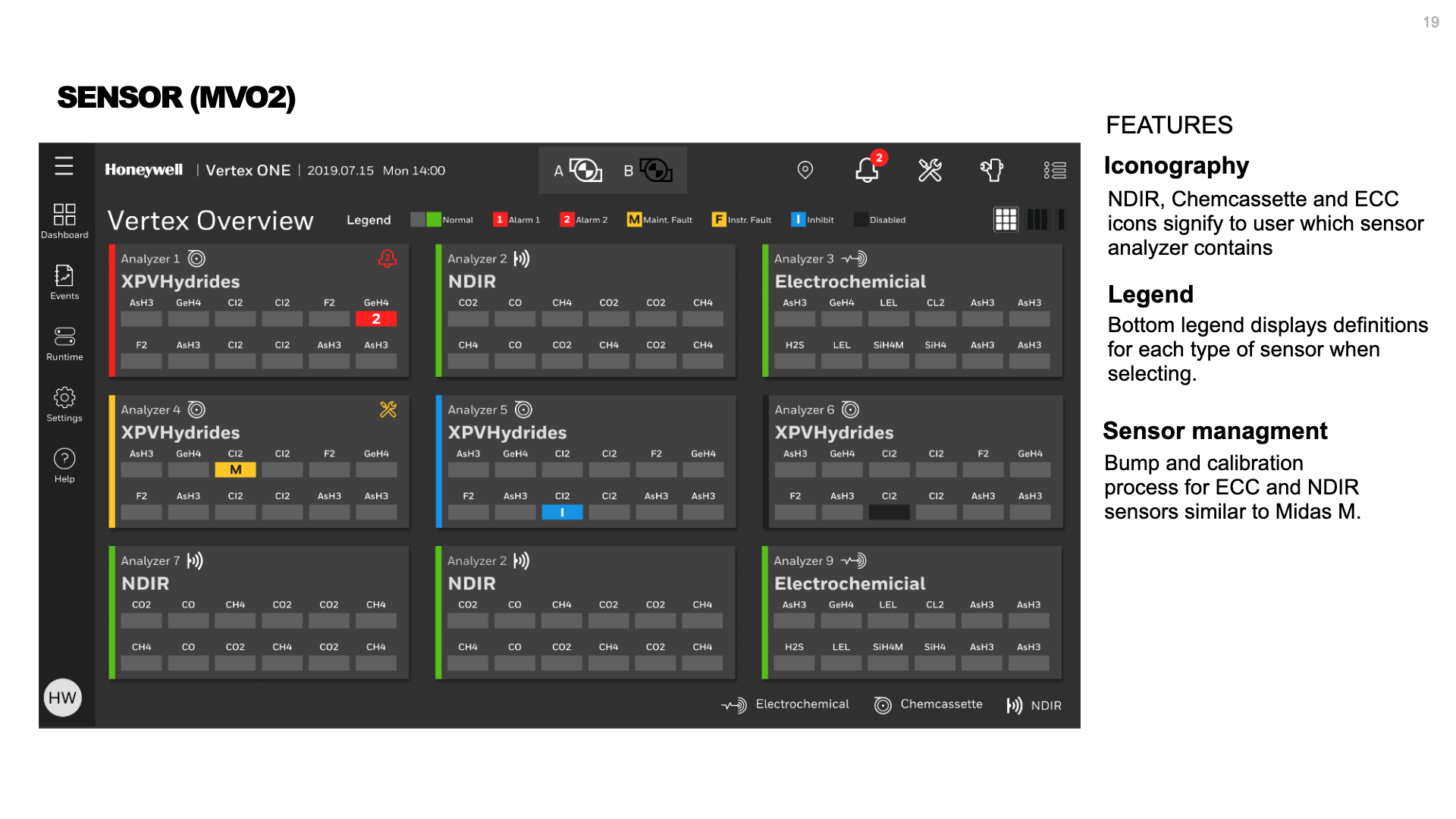

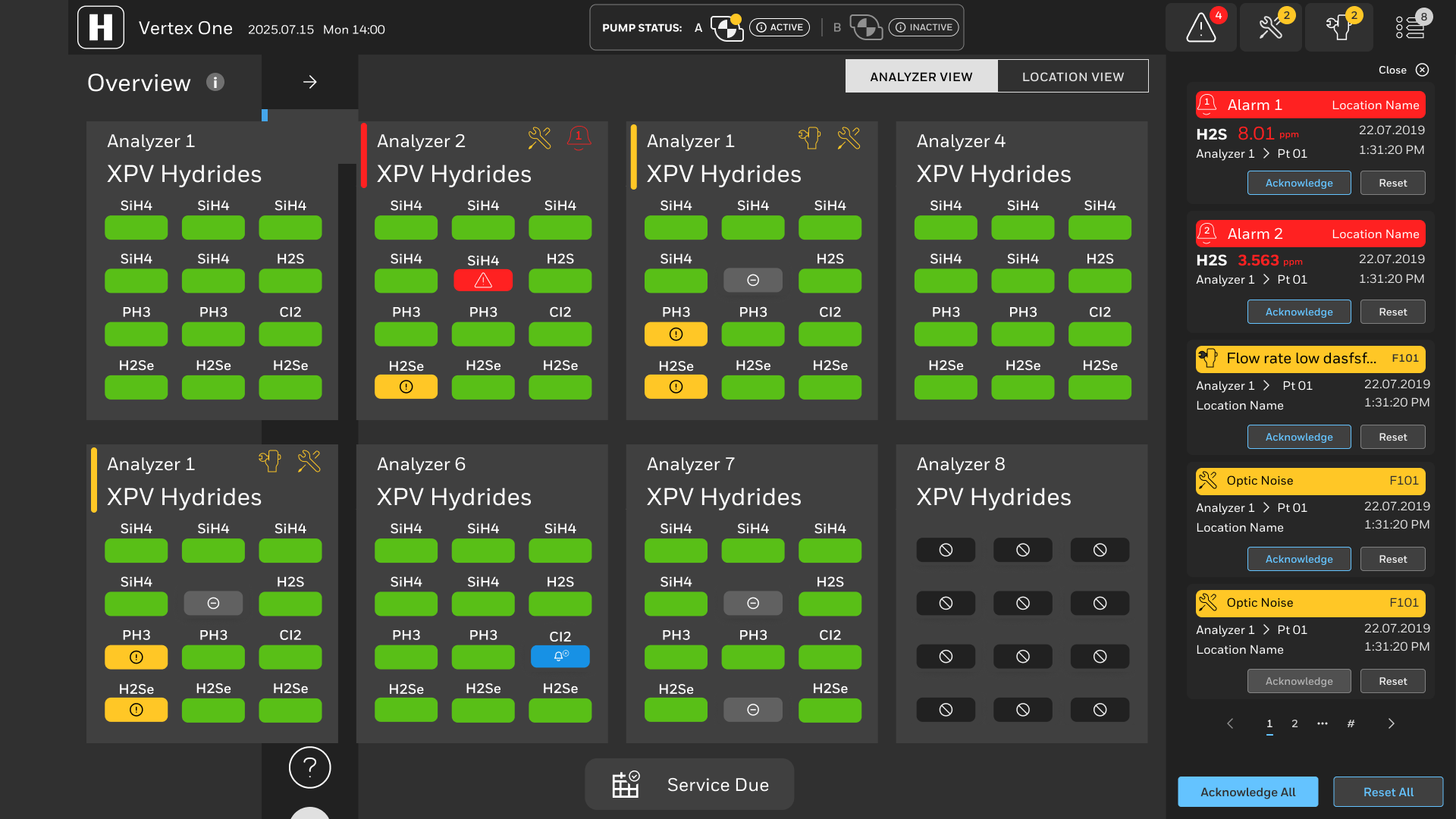

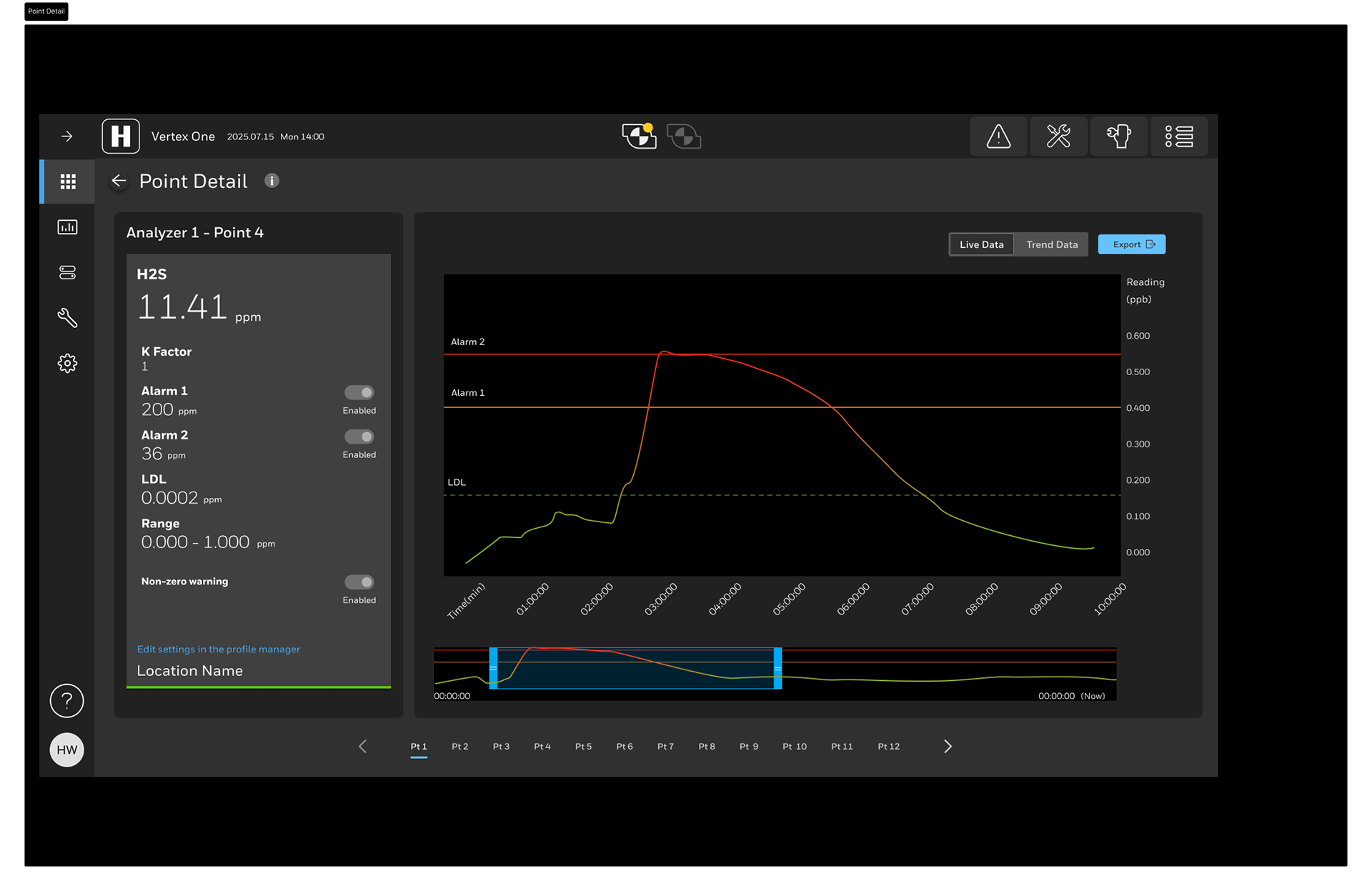

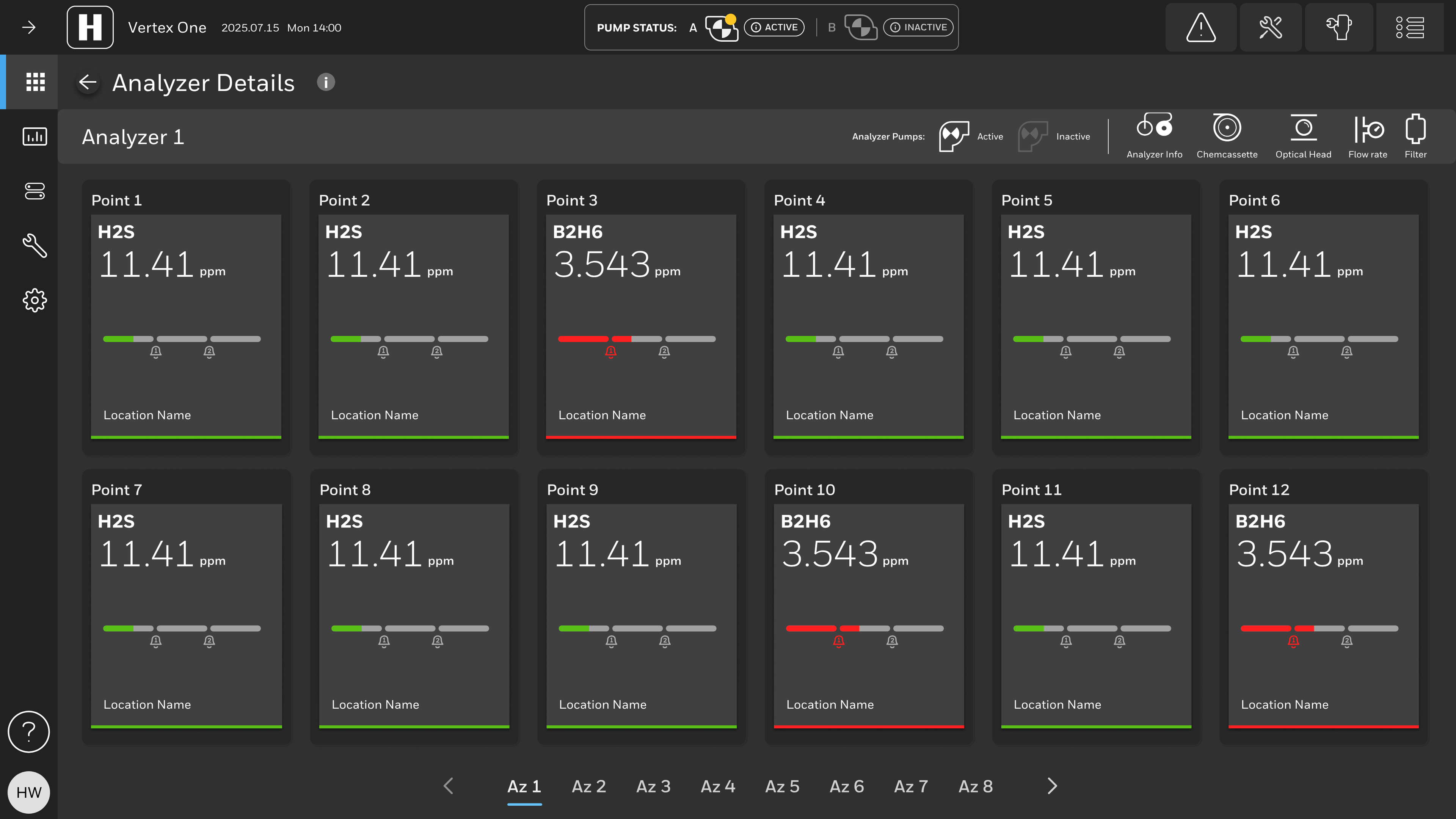

Concepts: Overview Analyzer Details and Point Detail Screens

Analyzer overview screen display point alarm and faults with special consideration for low vision and color blind users as red and green is a common challenge for color blind users. Alarms and fault notifications are automatically revealed in real time via a side panel with prominent, high-contrast indicators. The pump status in the header is easier to digest and more descriptive of faults since this is one of the differentiators the new Vertex.

Analyzer details show an overview of points with graphical representation of current concentration levels so field technicians can view when a point may be approaching the danger zone.

Chart visualizations and information at the gas detection point level clearly give an indication of when the gas event exceeded thresholds and can be easily exported.

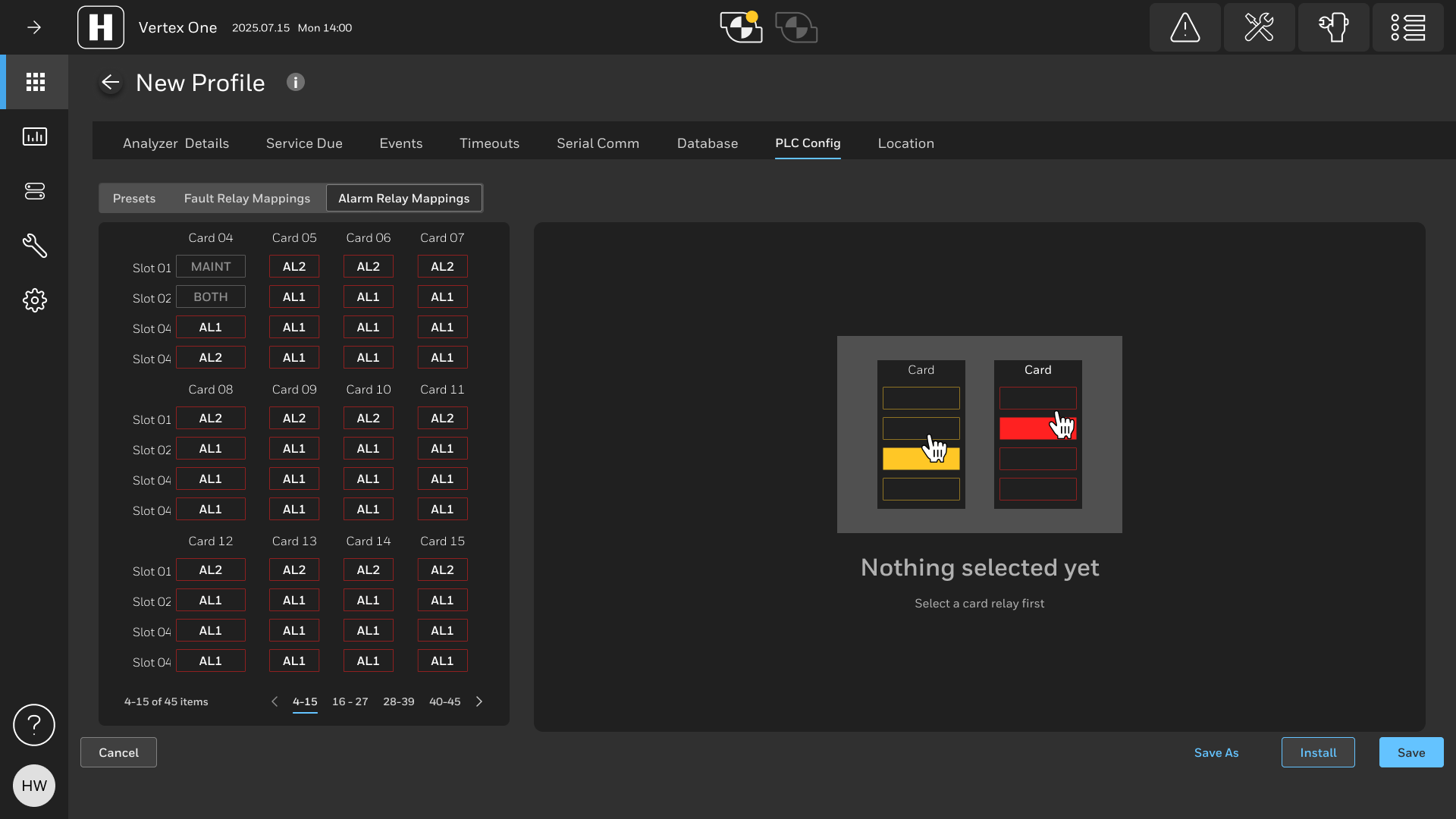

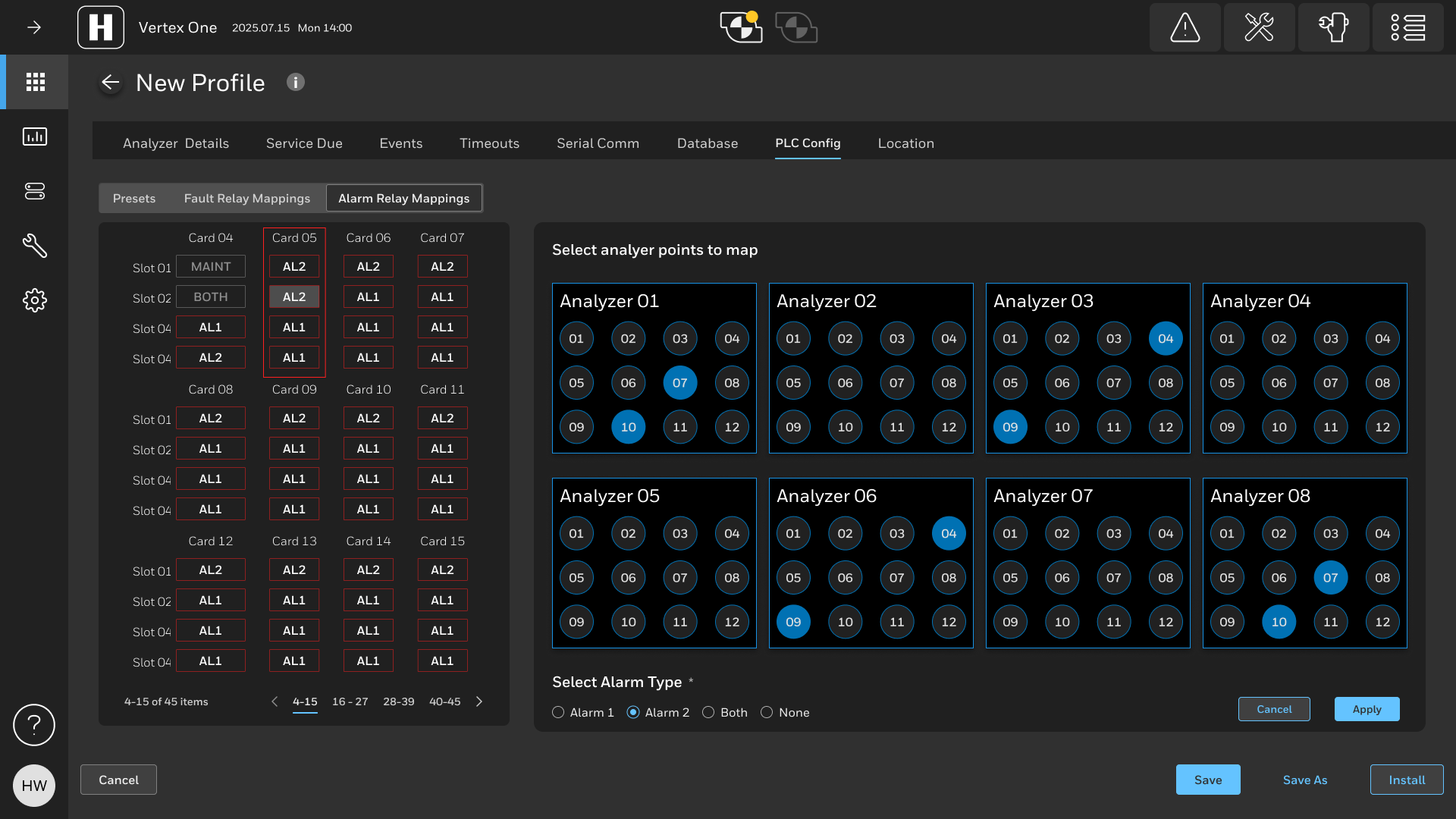

Concept: PLC touch configurator

As the result of tech support ticket analysis, interviews with field service technicians and observation of safety managers we heard and saw that configuring the PLC was too cumbersome. This fixed with the one-of-a-kind PLC touch configurator that gamifies the complex task. The idea came from selecting seats in a stadium when purchasing a ticket and mapping that to the number of people attending.

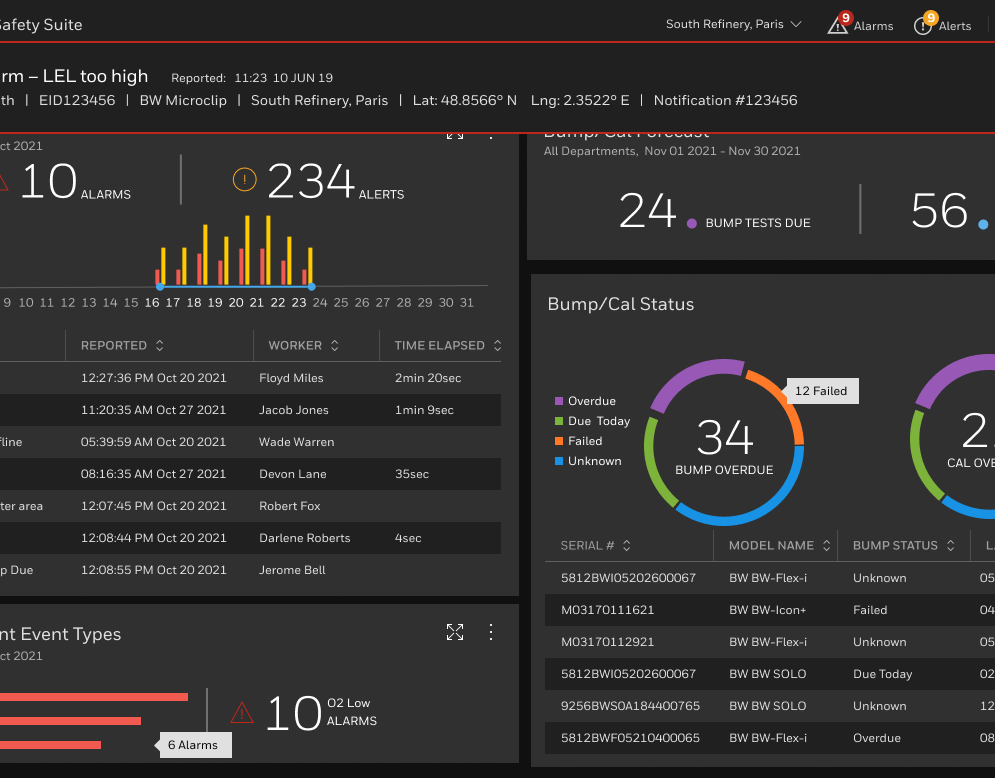

Analytics and Event History

Field service technicians and safety managers wanted more insights into faults and alarms on the Vertex. We provided easy to digest visualizations that also helped with the quarterly reporting process for customers. The resulting savings could amount to $1M+ annually and increase revenue for Honeywell in the high tech space.

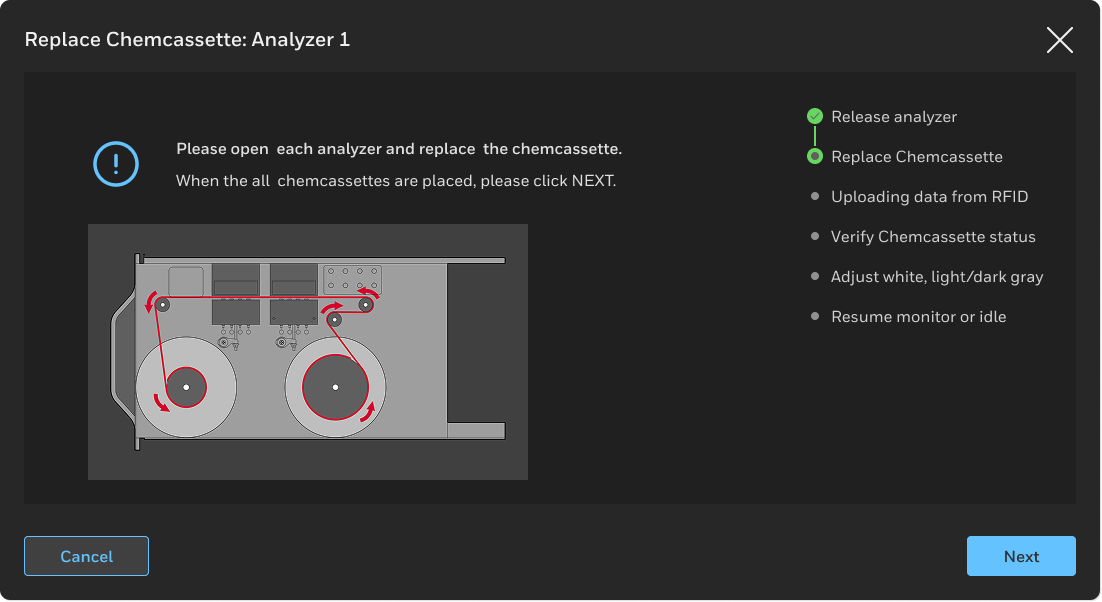

Training and Guided Maintenance

We heard repetitively that documentation was lacking and that training was needed. We solved this by explicitly detailing the steps of complex tasks like replacing Chemcassettes while providing instant and descriptive feedback for any errors. The user can go forward, skip or go back on any step so there is the ability to recover from errors.

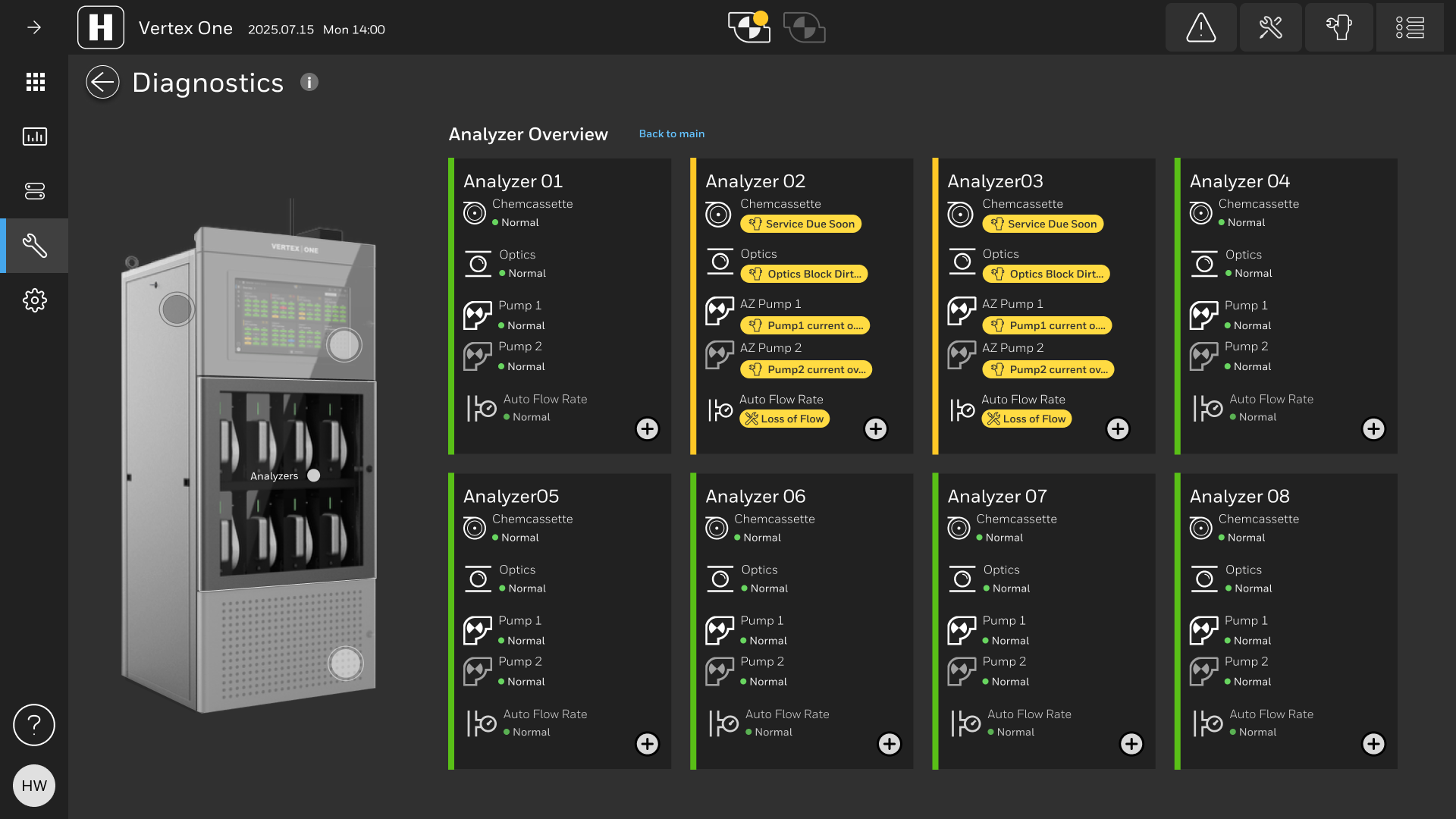

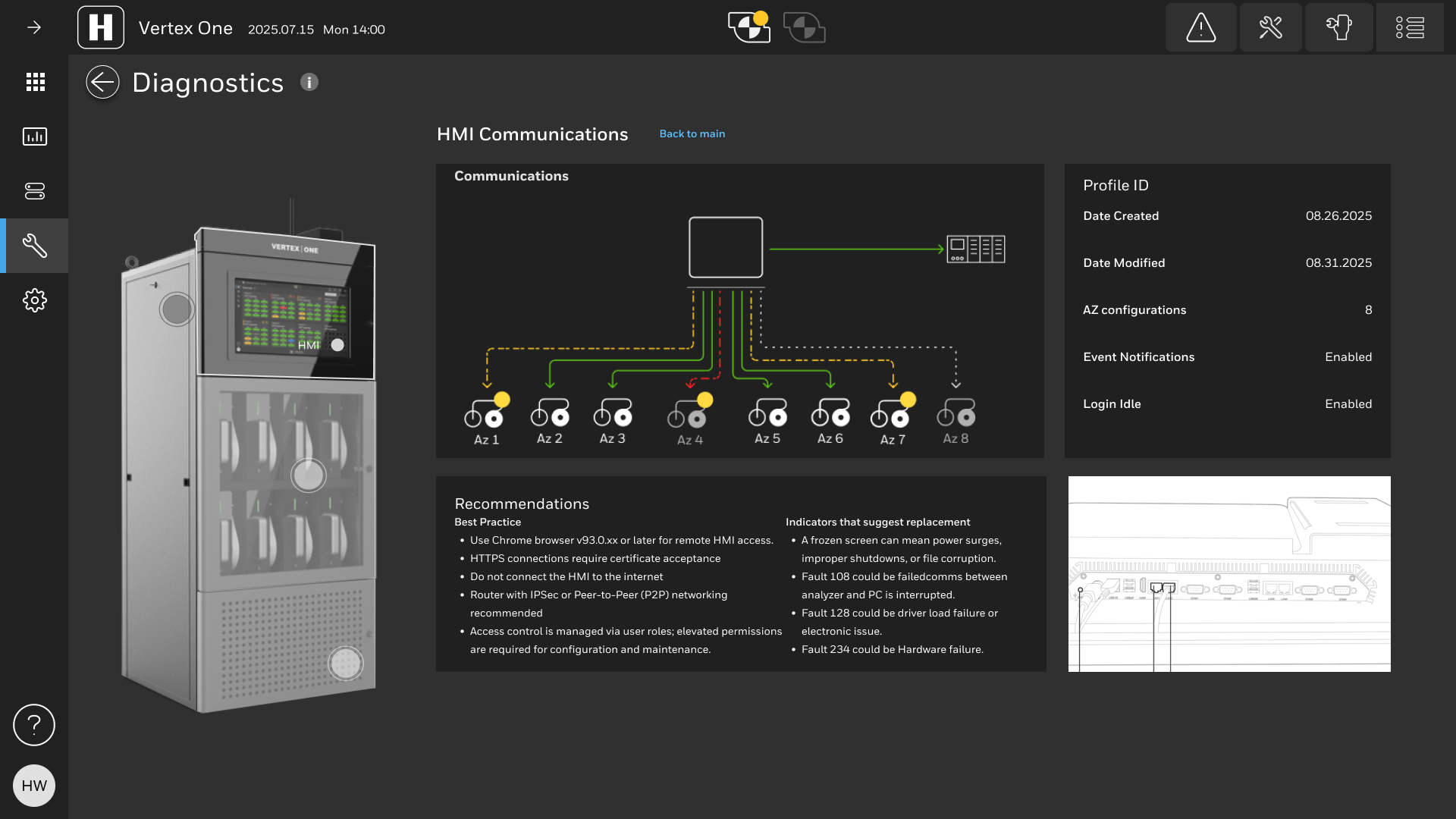

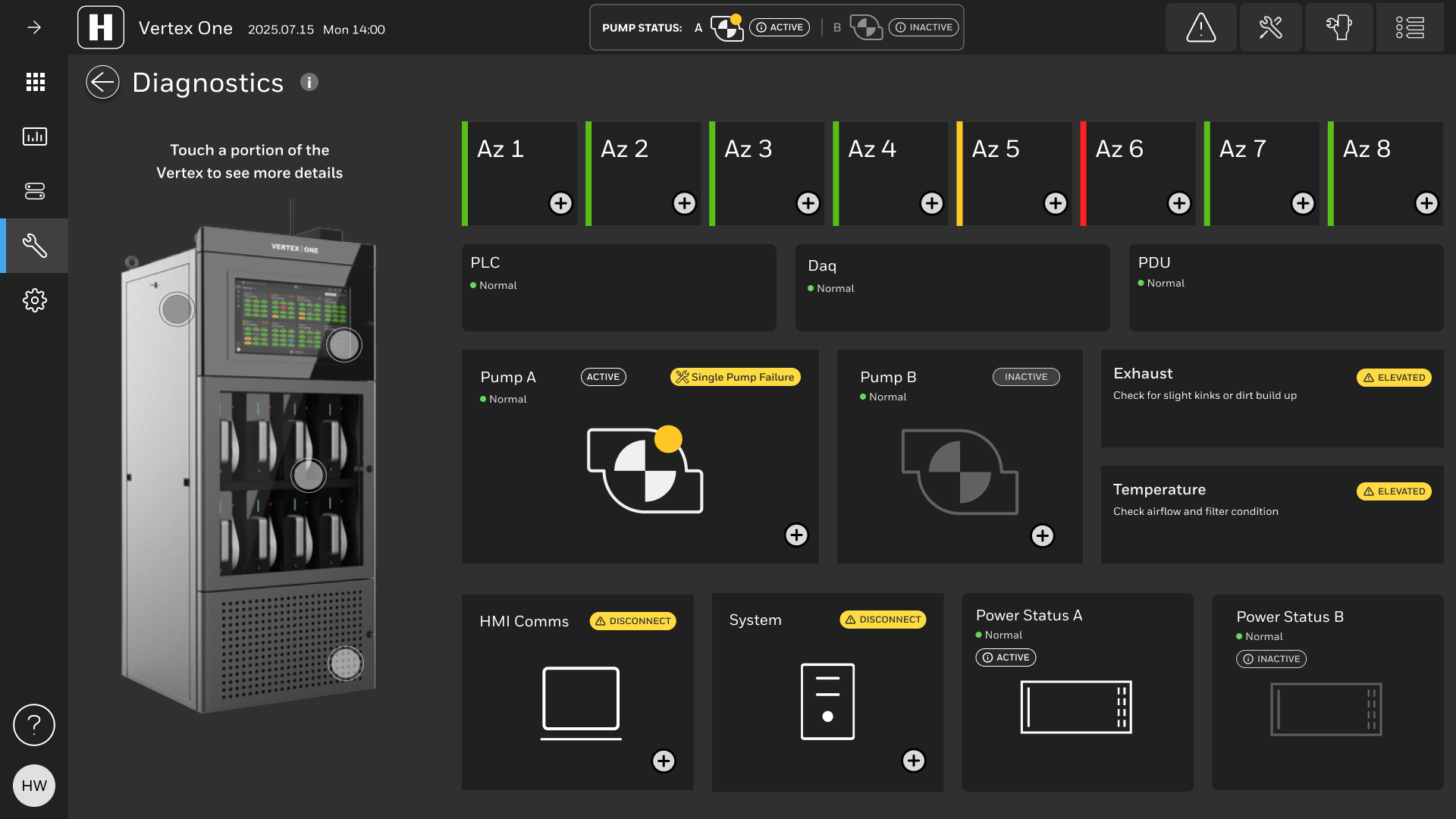

Diagnostics and Recommendations

Ideas circulated around specific recommendations with the rise of artificial intelligence. Internal stakeholders loved this feature including FSEs with many years of experience. The recommendations synthesized from various data sources could be a game changer for Honeywell and allow technicians to spend more time with the customer and less time figuring out how to troubleshoot edge case issues. The digital twin aspect of the diagnostics section received applause from sales, marketing and technicians.

"With the analytics and diagnostics ... This is something we can sell" - Honeywell High Tech President

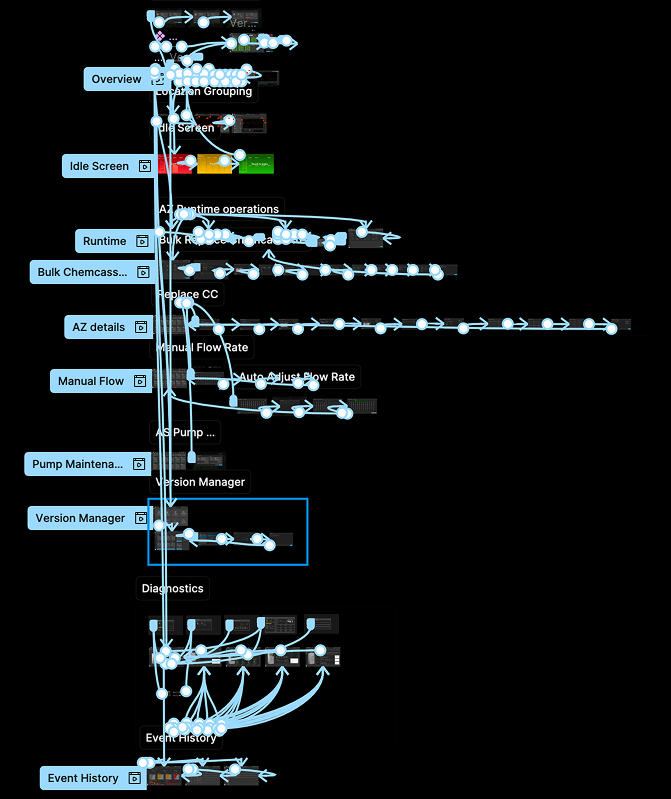

High Fidelity Prototype

The prototype helped to test the final screens with users and internal stakeholders alike. Every screen was linked up to the prototype and we were able to hook it into a tablet that mimicked the actual Vertex machine.

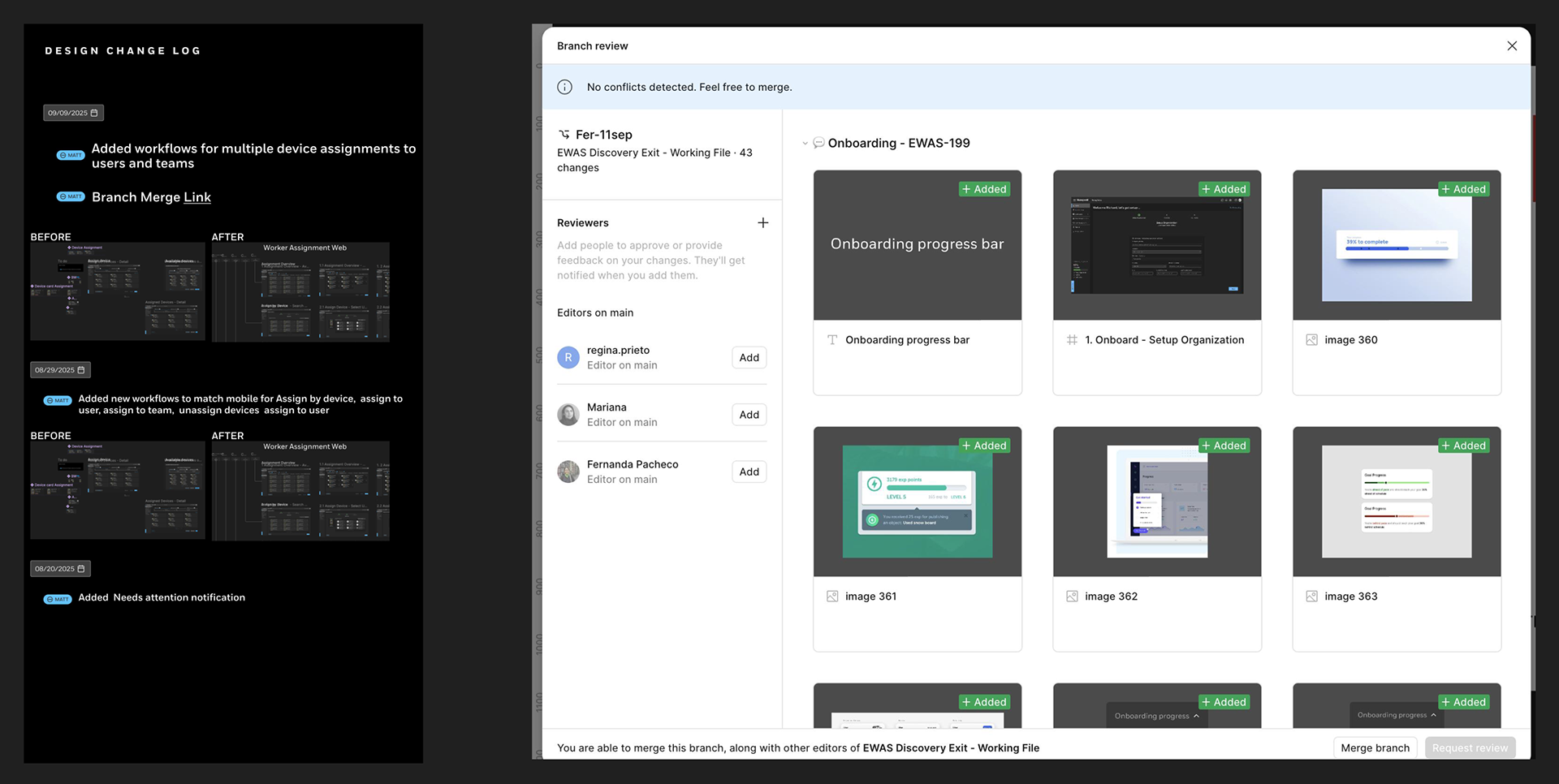

Versioning, Branching and Annotating

During the dev handoff process it's critical to keep designs updated when there will inevitably be minor tweaks. This is why I implemented a versioning system that included branch and merge functionality similar to GitHub. This native-Figma functionality allowed designers and developers to stay in sync and schedule updates after release in subsequent sprints. Annotating designs is another critical and often overlooked part of the design process. Annotations reduce the amount of back and forth between developers and stakeholders alike.

Prototype

The design actions for Vertex One led to an HMI solution recognized for its quality, successfully transforming a fragmented system into a cohesive, mission-critical interface, positioning it as a significant competitive advantage for Honeywell:

Presentations